What’s the Difference Between Self-Drilling and Self-Tapping Screws?

Despite their widespread availability and usage in commercial, industrial, and construction applications, many still confuse self-tapping screws with self-drilling screws.

Part of the reason this happens is that self-drilling screws are a subtype of self-tapping screws.

Let’s go through these two products separately to clarify these differences.

Self-Tapping Screws

Self-tapping screws have various names. They’re often called metal screws, sheet metal screws, tapping screws, or tapper screws.

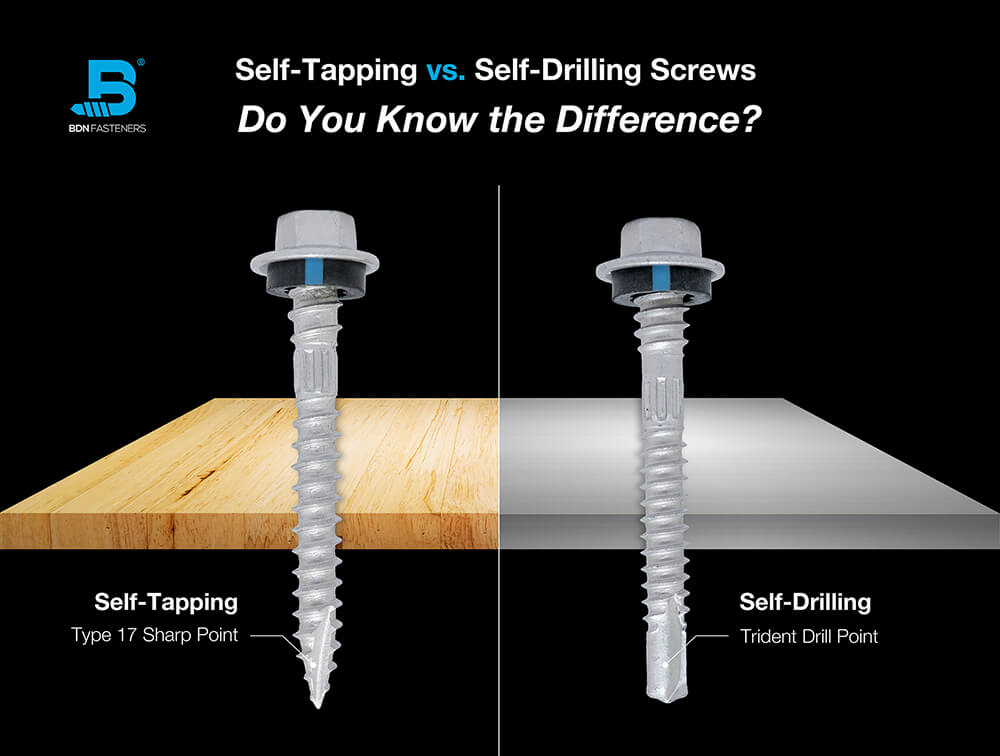

Their tips come in different shapes: pointed (like a pencil), blunt, or flat, and they are described as thread-forming, thread-cutting, or thread rolling. If the screw is pointed, it will be thread-cutting – tapping and creating threads in a pre-drilled hole. If the tip is flat, it is thread-rolling – rolling or extruding threads and creating zero clearance between screw and material.

When it comes to selecting the right self-tapping screw, it’s important to consider the material the screw will be used on. Different types of self-tapping screws are designed for specific materials, such as wood, metal, or plastic. The size and length of the screw should also be considered, as well as the desired level of torque, or tightening force, required for the application.

Self-tapping screws are generally easy to install and can be used with a variety of tools, including power drills and screwdrivers. However, it’s important to note that over-tightening can cause the screw to strip the threads, reducing its holding power. It’s also important to ensure that the pilot hole, or hole that the screw is inserted into, is the correct size and shape to ensure proper thread formation and holding power.

The most important difference between self-tapping and self-drilling screws is that self-tapping screws cannot go through metal without a pilot hole, which must be pre-drilled or pre-punched.

One of the main advantages of self-tapping screws is that they do not require pre-tapping, which is the process of creating threads in the material before inserting the screw. This eliminates the need for additional tools and can save time and labor costs. Additionally, self-tapping screws can be used in materials that are too thin or brittle to be pre-tapped, making them a versatile choice for a wide range of applications.

Exact drill or punch hole size is also important. The screw will become loose and not thread properly and securely if the hole’s too big. If the hole’s too small, the screw can break or cause the material to split or crack.

Self-tapping screws are good for use with metals, various types of plastics (plywood, fiberglass, polycarbonates), and cast or forged material, like iron, aluminum, brass or bronze. Self-tapping screws also work for surfaces where you can’t secure the rear end with a nut. Common applications include fastening aluminum sections, attaching metal brackets onto wood, or inserting screws into plastic housings.

In conclusion, self-tapping screws are a versatile and convenient option for creating threads in a variety of materials. They are easy to install and can save time and labor costs, making them a popular choice for many applications. By considering the material, size, length, and thread pattern of the screw, and by following proper installation techniques, you can ensure that your self-tapping screws will provide a secure and reliable hold.

Self-Drilling Screws

Self-drilling screws are easy to distinguish if you look at their point, which curves gently at the end and is shaped like a twist drill. They’re often called Tek Screws, after the brand name that popularized them.

Self-drilling screws are generally easy to install and can be used with a variety of tools, including power drills and screwdrivers. However, it’s important to note that over-tightening can cause the screw to strip the threads, reducing its holding power. It’s also important to ensure that the pilot hole, or hole that the screw is inserted into, is the correct size and shape to ensure proper thread formation and holding power.

Screw lengths vary, but drill points are standardized, identifiable by number (1 to 5), which determines their length and thickness. Head and drive styles vary; self-drilling screws are most commonly Phillips, hex, or square.

Unlike self-tapping screws, self-drilling screws need no pilot hole to cut and fasten; they can drill, tap, and fasten in one go, which saves you the extra step of drilling, then fastening.

When it comes to selecting the right self-drilling screw, it’s important to consider the material the screw will be used on. Different types of self-drilling screws are designed for specific materials, such as wood, metal, or plastic. The size and length of the screw should also be considered, as well as the desired level of torque, or tightening force, required for the application.

Another important factor to consider when using self-drilling screws is the tip of the screw. Self-drilling screws come in a variety of tip styles, such as a fluted, split-point, or a self-centering tip. These different tip styles are designed to help guide the screw through the material and prevent it from wandering, which can lead to a poorly formed hole or damaged material.

These screws can fasten metal to metal, wood to metal, and work well with light, low-density materials. In general, they have more specialized applications than self-tapping screws. They are good for metal building and light gauge metal assemblies; Point #5 is already capable of fastening half-inch steel sheets.

Self-drilling screws are useful in HVAC applications, cladding, metal roofing, steel framing, and other general construction tasks.

In conclusion, self-drilling screws are a versatile and convenient option for creating threads and drilling hole in a single step. They are easy to install and can save time and labor costs, making them a popular choice for many applications. By considering the material, size, length, and tip of the screw, and by following proper installation techniques, you can ensure that your self-drilling screws will provide a secure and reliable hold.

Similarities and Differences

What’s most similar about these two types of screws is that both form threads as they penetrate the material being worked with. Both attach steel on steel and steel on wood when rivets or nuts and bolts cannot do the job.

Between these two, however, self-drilling screws offer two distinct advantages: time and costs saved at assembly time, and reduced error in installation, which often happens if one pre-drills holes in the wrong size.

Consult with self-drilling screw manufacturers you can trust – contact BDN Fasteners today.