How to Master Use of Self-Drilling Screws

Self-drilling screws – commonly known as Tek screws – are some of the most widely used metal fasteners in the building and construction industry.

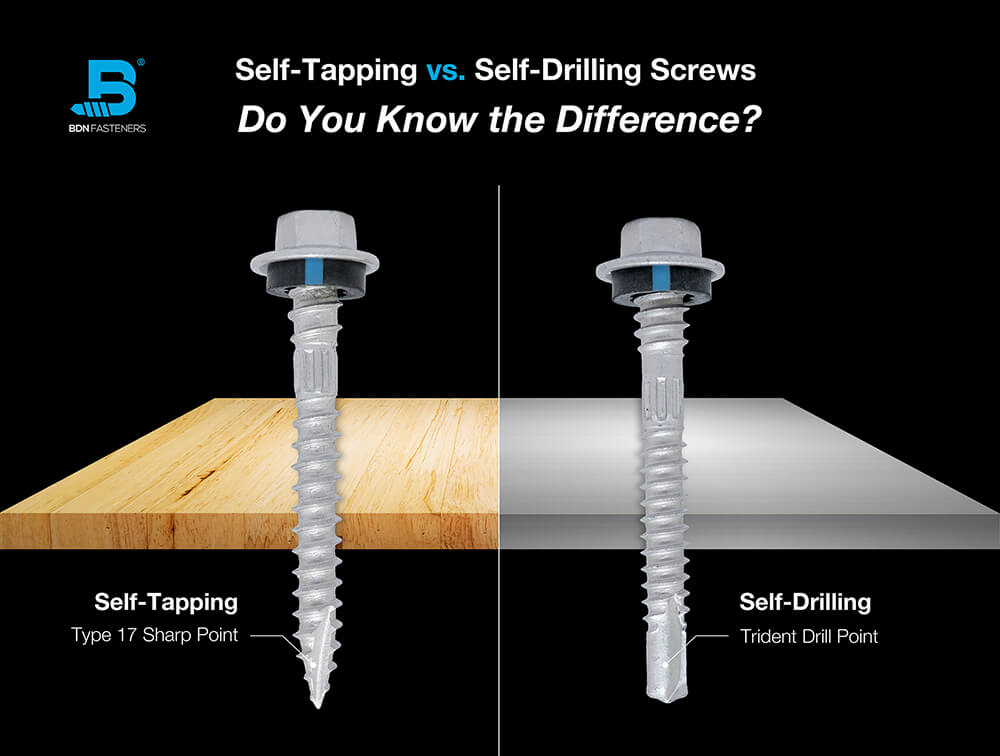

Tek screws or self-drilling screws come with an additional pair of bladed flutes which extends from the threaded portion of the body all the way to the drilling tip. The purpose of this is to combine the drilling and tapping function onto the same screw, thus eliminating the need to pre-drill pilot holes and tap threads. Drill, tap and fasten are completed in one go, saving time and money. The best Tek screws come with various types of surface treatments to cope with the environment and provide weathering resistance to itself and the fastened substrate.

Tek screws are popular for many general sheet metal applications like roofing, cladding, and HVAC, etc.

Larger Tek screws (No.3 Tek and above) are strong enough to penetrate 12~20-gauge galvanized steel, as well as 3/8” to ½” (10~12.5 mm) structural steel and can be used on various civil and naval engineering applications.

What is the best way to use Tek Screws?

To ensure optimum use and extended lifetime, here are some tips and recommendations for fastening Tek screws successfully onto various kinds of metal material.

- Choose the right size Tek screw to match the material you are working with.

Make sure that the Tek screw drill point capacity exceeds the thickness of the material to be drilled. Failing to do so may result in burnt out or broken drilling tips.

- Power drills with adjustable clutch settings are better suited for use with Tek screws on light sheet metal than Impact drills.

The hammering action generated by impact drills can cause metal dimpling or oil canning deformations on lightweight metal sheets.

- Do not overtighten the Tek screw and washer when fastening them onto sheet metal. The washers should be compressed just enough to fill any uneven surface to provide a perfect seal.

Two things can happen if the washers are over-compressed. One, the sheet panel may deform from overtightening, and two, the exposed portion will be exposed to the sun and the elements, which accelerates the weathering process and reduces lifespan.

- When fastening Tek screws onto hardened galvanized or structural steel, set your (cordless) power drill clutch speed to approx. 1500 rpm, and apply steady, consistent, pressure throughout the process.

Drill speed exceeding 2300 rpm or more can result in premature drill point wear or burnout, causing it to lose its function.

Do not compromise the quality and workmanship of your construction projects. Your building is only as strong as its weakest fastener. Choose only quality self-drilling screws from a reliable Tek screw manufacturer – Choose BDN Fasteners today, every day.