4 common causes of metal roof leaks around screws

Metal roof leaks around screws:

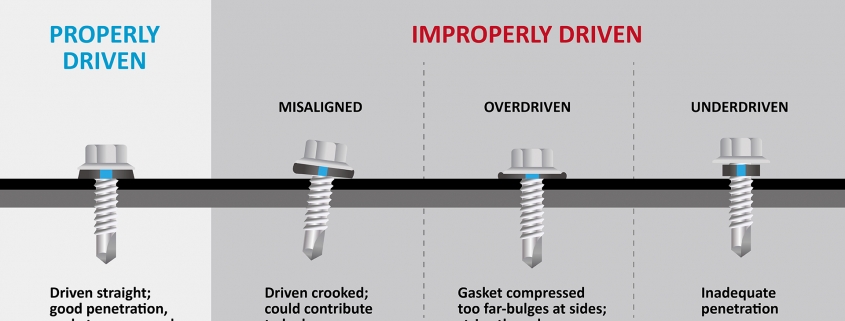

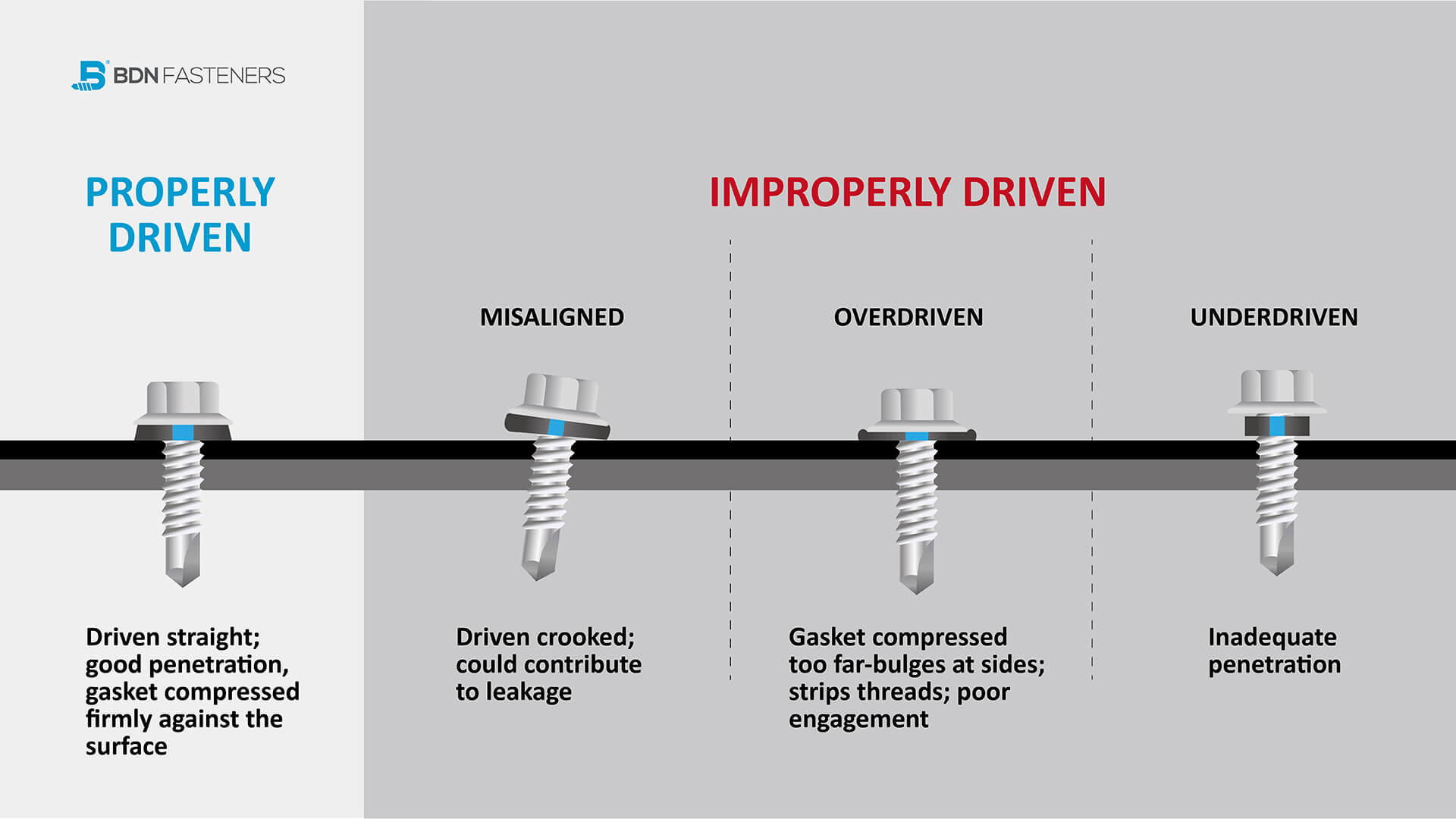

There are lots of contributing factors when it comes to roofing leaks. A properly driven screw will have achieved the following steps and as a result, provide the perfect weather seal.

Driven straight, perpendicular to the material it is fastened on to.

Adequate, clean penetration with no excess swarf protruding or overhanging from the drilled hole.

Driven until the gasket is compressed firmly against the surface.

Below is a list of common causes of metal roof leaks.

1. Choosing an incorrect screw:

Metal roofing screws are usually designed for fixing thin roofing sheets onto steel purlins, trusses or timber underneath. Depending on the thickness of steel underneath, correct drilling point sizes must be chosen in order to penetrate. Most suppliers will provide a list with corresponding drilling capacities to their screws. Read through the list carefully and don’t hesitate to ask questions.

The length of the screw is also important. The length of screw required can be calculated by adding the depth of the roofing sheet corrugation, plus the thickness of the purlin/truss underneath plus at least 2 to 3 full thread lengths to ensure proper fastening. Don’t forget that the thickness of the bonded EPDM washer or Domed BAZ washer should also be taken into consideration.

Thread type should be considered. A rule of thumb is, coarse threads for thinner sheets (<4.5mm), and fine threads for thicker sheets (>4.5mm). This will ensure the fixing to have adequate pullout values against pressure from high winds or snow.

2. Over–driven screws:

The rubber gasket should seat firmly but not over compressed against the surface. The rule of thumb is, the gasket should not be bulging at the sides of the washer flange, or even to the point of being squished. Workers should take extra care while making an attempt to ensure a tight seal between the metal roofing and the screw head because an over-torqued washer loses its elasticity, breaks down prematurely, and oftentimes disintegrate due to over-exposure to the elements.

3. Under-driven screws:

This is an easy one. An under-driven screw does not provide sufficient pressure to the washer to create a firm seal against the surface. This may happen due to incorrect drilling tip capacity selection and therefore could not adequately penetrate the metal substrate underneath to reach the desired depth.

4. Misaligned or skewed drilling:

A misaligned or crooked driven screw will result in the rubber washers not seating properly against the surface, which means insufficient seal of the hole, or one side over compressed, resulting in premature damage to the gasket. Another sometimes overlooked risk is the skewed side of the steel washer or hex washer flange digging in, deforming or sometimes even cracking the surface, which also contributes to leakage.

Some screws have extra features built in to enhance performance; oftentimes poor choice of fixings become the weakest link in a seemingly strong building structure. BDN Metal-Tite® series roofing screws come with an enlarged hex washer flange, anti-static EPDM washer, double thread, Scratshank, and Ruspert anti-corrosive coating.

- The large washer flange is designed so that the EPDM washer will remain fully covered after compressed.

- Anti-static EPDM washers prevent galvanic corrosion.

- The larger diameter upper thread close to the hex washer flange increases pullout values on thin metal sheets.

- Scratshank clears out excess swarf, smooths out the drilled hole, and prevents damages to the EPDM.

- Ruspert anti-corrosive coating fully protects the screw from weathering and extends the lifespan of the screw and the sheets it is affixed to.

Learn more about BDN Fasteners >>

Internal Roof Insulation Installation with Self-Drilling Fasteners

How to use self tapping screws for metal?