What Are Pilot Holes? When and Why You Should Use Them

What are pilot holes? This guide covers everything you need to know—including when to drill them, why they matter, and how to choose the right size for wood, metal, and more.

What Are Pilot Holes? Why Should You Use Them?

What are pilot holes? They are small holes drilled into a piece of construction material, be it steel, timber, plastic, ceramic and more.

The main purpose of drilling pilot holes may be:

- To prevent potential damage or cracking of the material when making a large hole is required.

- To pinpoint the exact location where screws or fixtures go on smooth or slippery surfaces where there isn’t enough space for second chances.

- Pilot holes help prevent splitting or cracking when screws or nails are driven in wood and other materials.

- Making larger holes on materials (normally plastics) which require thermal expansion holes.

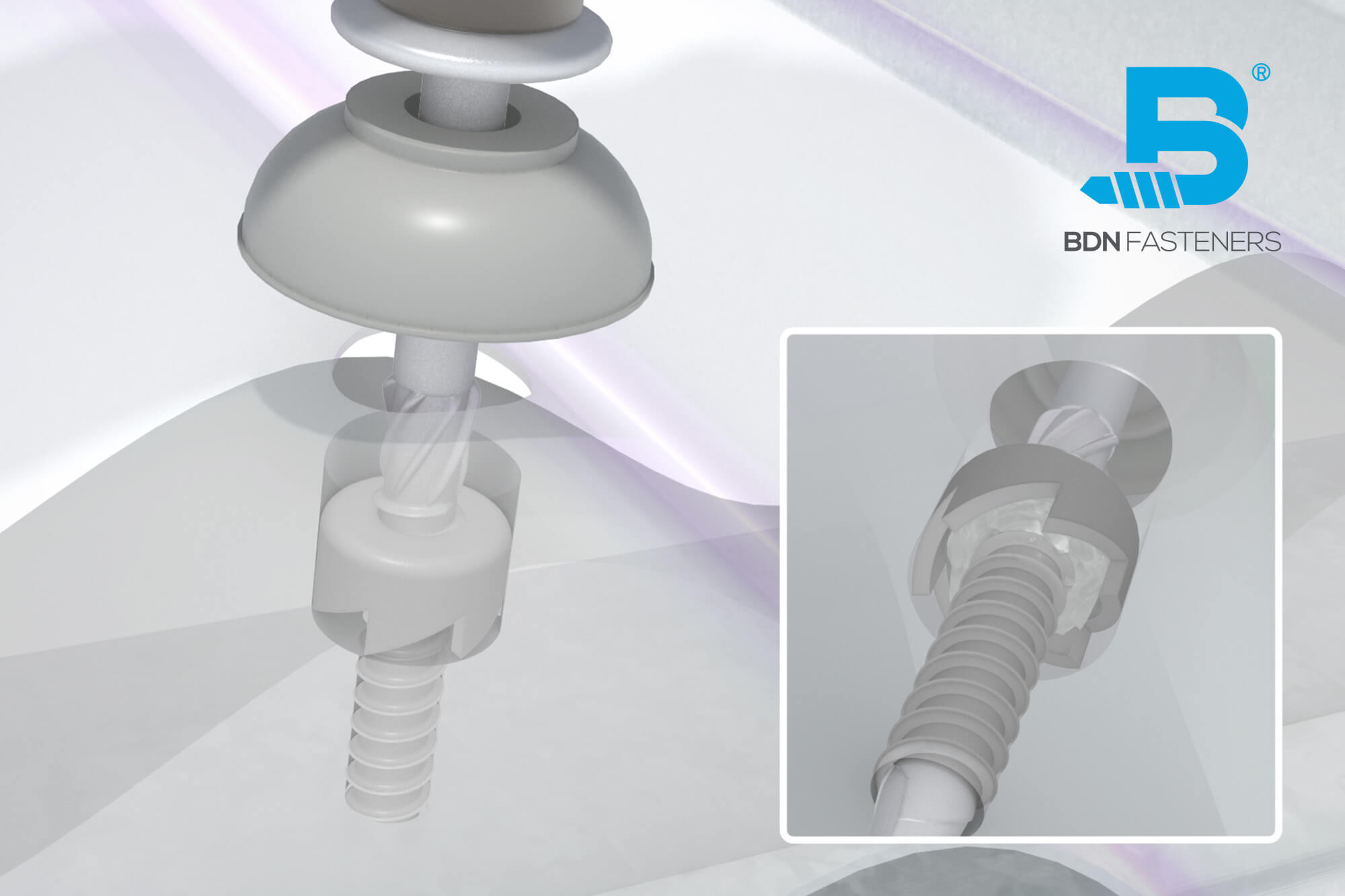

To locate, guide or clear out excess material for self-tapping screws in hard wood or plastics to prevent damaging the material or burning out the screws.

When Is a Pilot Hole Necessary? 5 Scenarios You Should Know

1. Pilot Holes for Larger Holes

Pilot holes can be drilled to its full extent or half-way through (depth) depending on the purpose. Pre-drilling pilot holes reduces the torque required for drilling a large hole in on-go, therefore reduces risk of damaging the drill and the substrate that is being penetrated. If very large holes are required, the drilling process may be split into multiple steps until the final size is drilled.

2. Pilot Holes on Slippery Surfaces

Oftentimes, very hard or smooth surfaces such as most metals and plastics, fixtures such as self-drilling screws tend to wander during the initial drill and drive process. A center-punch can be used to pinpoint the exact location prior to creating the pilot hole.

3. Pilot Holes on Tough Surfaces or Hard Material

On tough surfaces, hard materials or in wood, pilot holes help prevent splitting or cracking that could result from drilling a larger hole in one go.

4. Pilot Holes for Thermal Expansion

Plastic materials such as polycarbonate (sheets) have a high coefficient of thermal expansion compared to steel or wood, which means that the polycarbonate sheets tend to shift and move when temperature ranges are significant. Drilling a pilot hole that has a larger diameter than the fixture gauge can prevent sheets from being damaged when the shifting happens.

(Read more: Polycarbonate Roofing Fixing Instructions: 8 Roof Fixing Tips)

5. Pilot Holes for Fixing through Tough Materials

When it comes to drilling and fixing through tough materials such as hardened steel or hard wood, pre-drilling pilot holes can be a blessing. This will eliminate the need for heaving duty fixings that must be used to drill through the substrate but can be totally unnecessary to fix the attached material, which is often just a thin piece of sheet metal or plastic glazing.

When fixing material to hard wood substrates, drilling a pilot hole can prevent the wood from splintering during the process, as often, you only get one chance at fixing the attachments correctly.

How Do You Choose the Right Drill Bit for a Pilot Hole?

Choosing the right drill bit for a pilot hole is equally important as the pilot hole itself. Although important, it is not complicated at all once you have learned the knack of it. A pilot hole that is too small can cause the wood to split, which is exactly what you want to prevent. Conversely, a hole that is too large won’t provide enough grip for the screw threads, reducing their holding strength.

Pilot Hole Size Chart for Steel Substrates

| Screw Size (#) | Screw Diameter (inches / mm) |

Pilot Hole Size (Steel ≤ 1/8″) |

Pilot Hole Size (Steel > 1/8″) |

| #6 | 9/64″ / 3.5 mm | 3/32″ / 2.4 mm) | 7/64″ / 2.8 mm) |

| #8 | 5/32″ / 4.0 mm | 7/64″ / 2.8 mm) | 1/8″ / 3.2 mm) |

| #10 | 3/16″ / 4.8 mm | 1/8″ / 3.2 mm) | 9/64″ / 3.6 mm) |

| #12 | 7/32″ / 5.5 mm | 9/64″ / 3.6 mm) | 5/32″ / 4.0 mm) |

| #14 | 1/4″ / 6.3 mm | 5/32″ / 4.0 mm) | 3/16″ / 4.8 mm) |

Key Considerations:

Thinner steel (≤ 1/8″) requires a smaller pilot hole to ensure proper thread engagement.

Thicker steel (> 1/8″) may need a slightly larger pilot hole to accommodate thread cutting.

Self-drilling screws often do not require a pilot hole but may benefit from one in thicker or harder steel.

Always follow manufacturer recommendations for the specific fastener you are using.

(Read more: Self-Drilling Screws for Metal: 7 Features that Simplify Projects)

Pilot Hole Size Chart for Woodworking

| Screw Size (#) | Screw Diameter (inches / mm) |

Pilot Hole Size (Softwood) |

Pilot Hole Size (Hardwood) |

| #4 | 7/64″ / 2.8 mm | 1/16″ / 1.6 mm | 5/64″ / 2 mm |

| #6 | 9/64″ / 3.5 mm | 5/64″ / 2 mm | 3/32″ / 2.4 mm |

| #8 | 5/32″ / 4.0 mm | 3/32″ /2.4 mm | 7/64″ / 2.8 mm |

| #10 | 3/16″ / 4.8 mm | 7/64″ / 2.8 mm | 1/8″ / 3.2 mm |

| #12 | 7/32″ / 5.5 mm | 1/8″ / 3.2 mm | 9/64″ / 3.6 mm |

| #14 | 1/4″ / 6.3 mm | 9/64″ / 3.6 mm | 5/32″ / 4 mm |

General Tips for Selecting a Pilot Hole Size

- Softwood (like pine, cedar, spruce) usually requires slightly smaller pilot holes.

- Hardwood (like oak, maple, walnut) usually requires slightly larger pilot holes to avoid splitting.

- Always drill the hole slightly deeper than the screw length to allow the screw to seat properly.

- When in doubt, test pilot hole size on scrap material first.

Still wondering what are pilot holes used for in other materials like masonry or composite panels? Contact us or your local BDN Fasteners® distributor for tailored advice.

Learn more about BDN Fasteners >>

Over-Torquing: A Technical Guide to Its Dangers and Prevention

How to Use Self-Tapping Screws? The Right Way to Install Them

How to Install Steel Studs? Expert Advice for a Professional Finish