Tek Screws for Different Applications: Top Uses and Benefits

TEK screws, also referred to and known as self-drilling screws, are designed for different applications. TEK screws feature a drilling bit that carve a hole through metal substrates, allowing the threads to subsequently go through to join or fix down. The invention of the TEK screws eliminates the need for pre-drilling pilot holes, making the job faster and more efficient.

BDN Fasteners offers a variety of Tek screws for different applications, each intended purpose and benefits listed below:

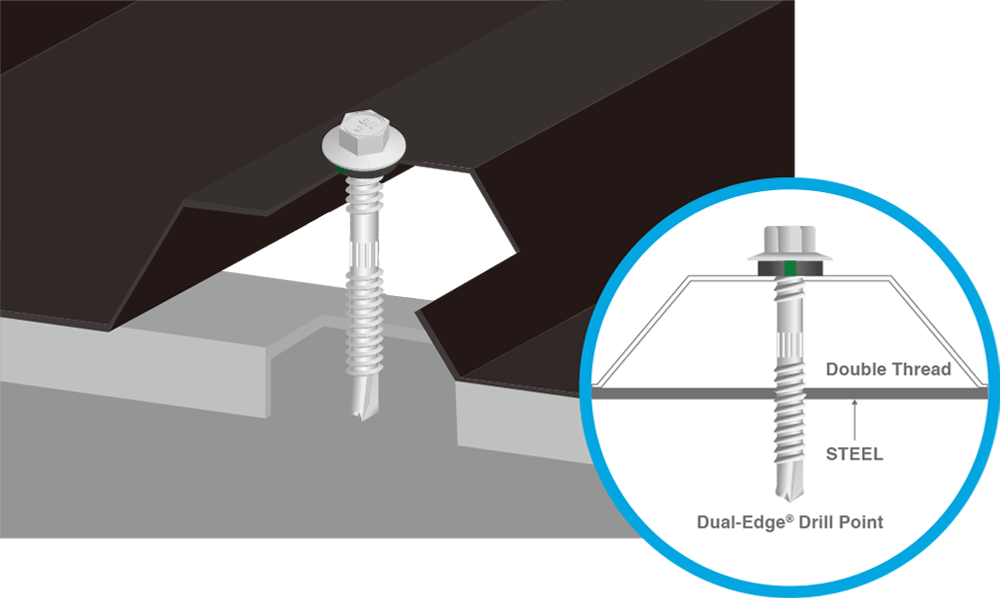

Crest Fixing Tek Screws

For fixing steel sheets at the crest onto steel substrates, purlins or rafters below, crest fixing on rooftops is crucial. This is because, due to gravity, water and debris always go to the lowest point possible. #12 diameter and above are normally used, as they provide better strength and support on rooftops.

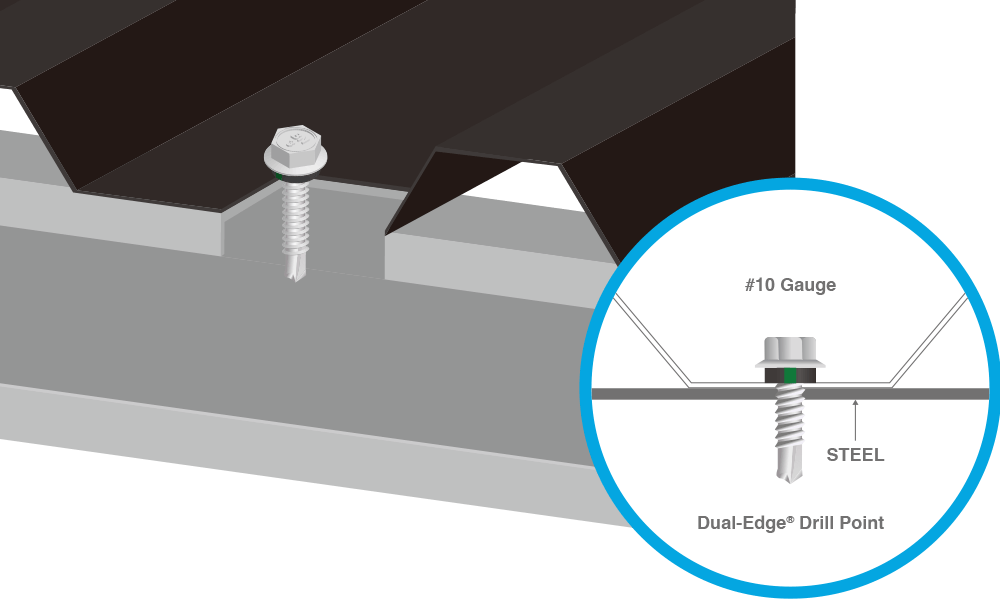

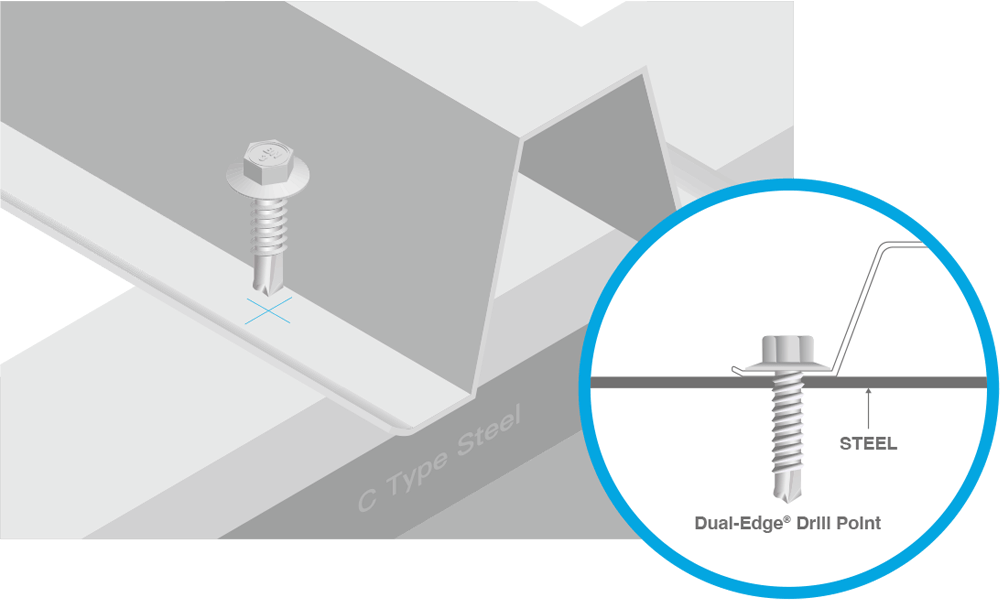

Cladding to Metal Tek Screws

Cladding or wall curtain profiles are usually affixed to thinner purlins or substrates; therefore, a smaller gauge, normally #10 screws will suffice. Wall curtains and claddings are normally fixed at corrugation valleys, where shorter screws are required.

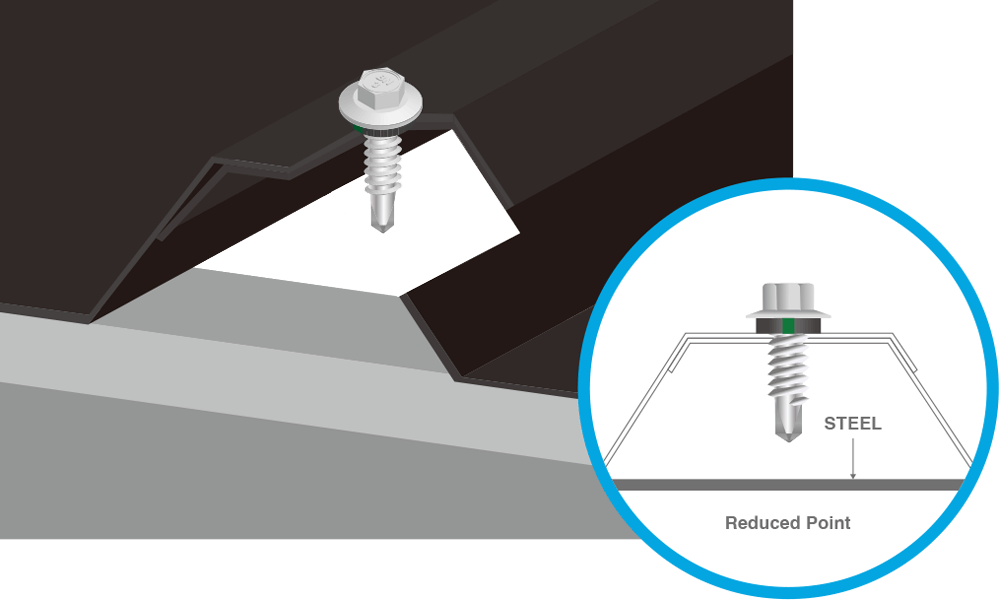

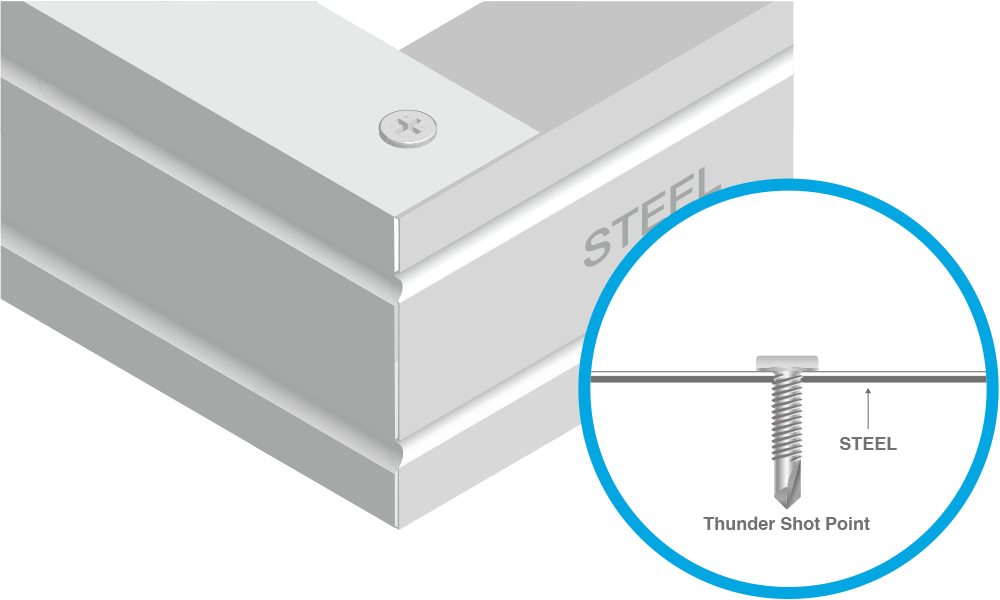

Stitching Tek Screws

Stitching Tek screws are normally used on lightweight panels, for side lap or end lap connections in light gauge steel. These screws benefit from a reduced, thunder-shot drilling point to avoid thread stripping, and when paired with our proprietary harpoon threads, they provide better pull-out strength.

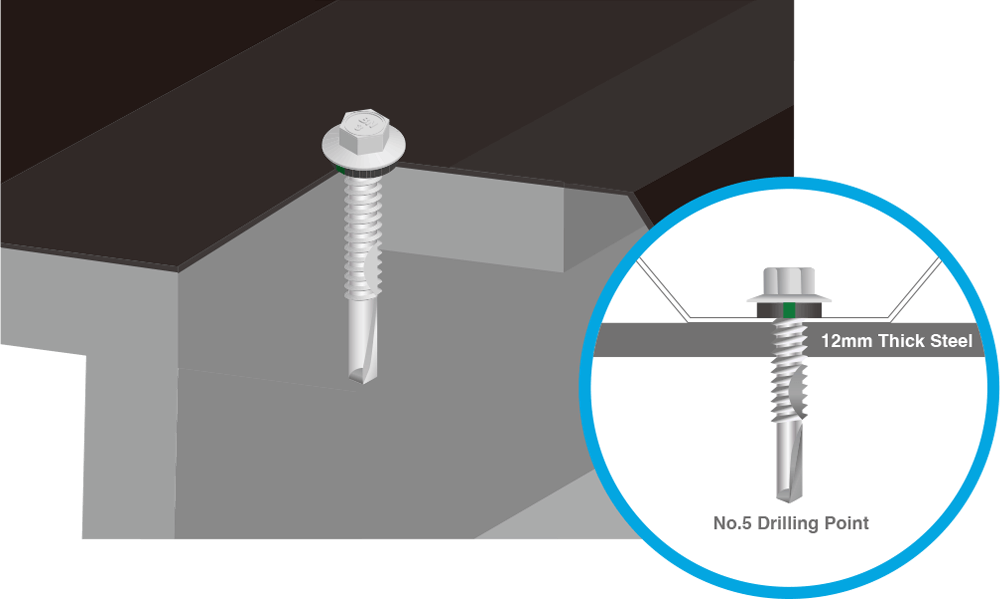

Heavy Duty Thick Steel Tek Screws

Our heavy-duty Tek screws come with patented thunder shot drilling point that prevents wandering, carves through and clears swarf brilliantly, drilling through 12.5mm thick steel with ease.

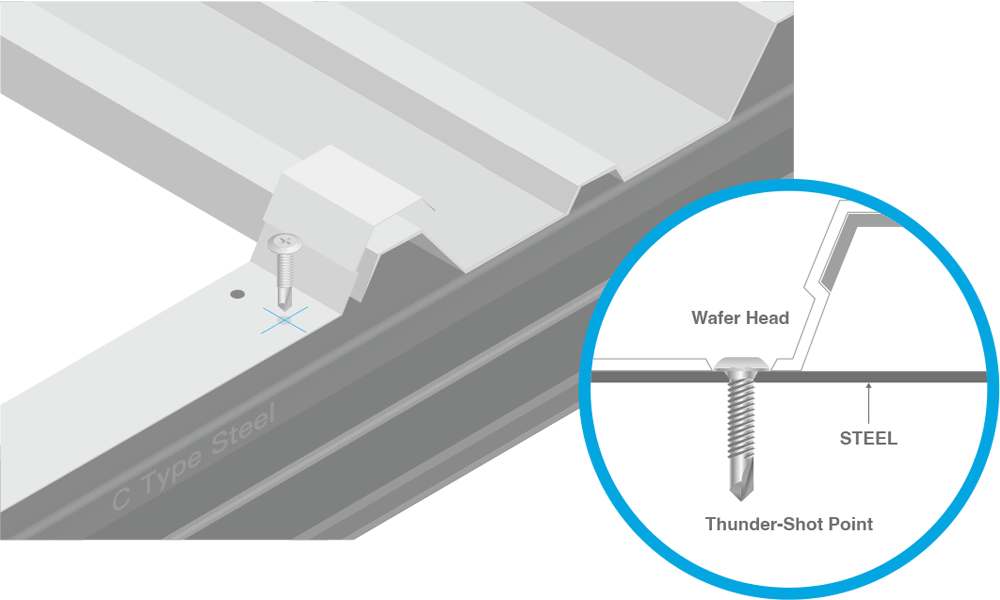

Concealed Fixing Tek Screws

BDN’s wafer head concealed fixing Tek screws not only has a low profile in itself, but retains its low profile upon fixing, creating an aesthetically pleasing flat surface without any protrusions which might create interference.

Truss to Plate Connection Tek Screws

BDN’s METAL-Tite truss-to-plate connection fasteners are designed to have a high pullout strength and paired with our patented Trident drilling point – the ultimate choice for fixing steel truss to steel plate or beam thicknesses ranging from 0.75mm to 1.6mm.

Frame Fixing Tek Screws

Our Frame Fixing Tek Screws are made for stud to plate or plate to lintel connections without pre-punched holes. Serrations under the head provide extra grip and prevent the screw from spinning when fixed.

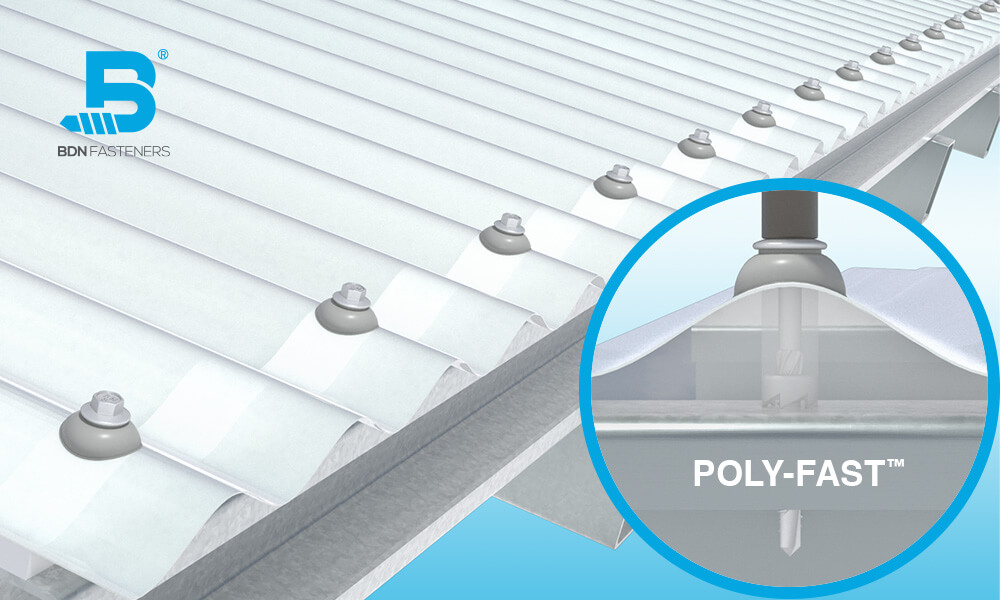

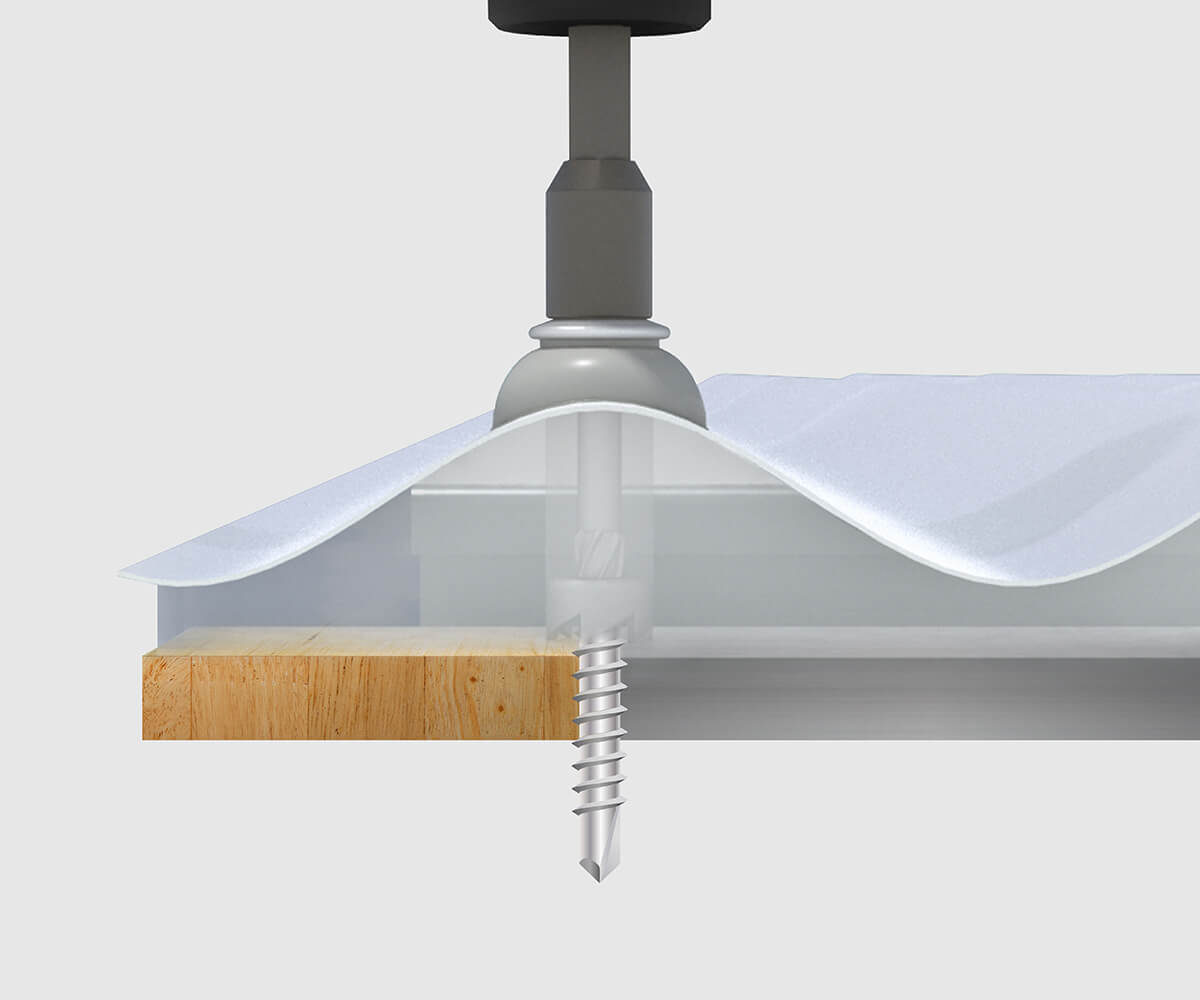

Plastic Skylight Tek Screws

BDN POLY-FAST skylight Tek screw creates an 11mm thermal expansion hole and fixes down polycarbonate plastic skylights securely to steel or timber purlins in one go. Extra features, such as the Depth Stop Knurls, work in conjunction with the expansion hole cutter to create a stopper, preventing overdrive and deforming of the skylight sheets.

For more information on the type of BDN Fasteners tek screws for different applications, top uses and benefits, please contact us.

Related Articles:

Are screws recyclable? Two stages of screw recycling process