What screws for metal roofing? Tips on choosing roofing screws types

When selecting fasteners and roofing screws types for specific projects, it is important for the builder, designer, and even installer to understand or be involved in the process to understand not only the material and available options, but to also check compatibility against the environment, and the most important of all, building regulations.

While choosing what screws for metal roofing are suitable, many might see their choice limited by budget or price-sensitive biddings, though we always remind decision makers to see it in a broader sense.

The cost of fixtures normally accounts for a fraction of the total budget, but plays a significant role in the overall safety and longevity of the structure, as a chain is only as strong as its weakest link – meaning a roofing sheet will have to remain in place be it rain, wind, or shine to protect what is covered underneath, and the main purpose of screws is to keep substrates securely joined or fastened to one another.

There will always be cheaper alternatives when it comes to building material choices, though one should always ask – what is the compromise? Are you willing to, in exchange for short-term savings, risk sacrificing safety and stability of the whole project in the long-term?

Questions to determine the correct roofing screws types

1. Determine the type of roofing sheets are we dealing with.

a. What material is the sheet made of?

b. What profile is the sheet?

c. What is the color?

d. Thickness of the sheet?

e. Is it an insulated panel? If so, what is the thickness of the insulated portion?

f. Will there be skylight panels involved during installation?

2. Determine the structure it is affixed to.

- Are the purlins steel or timber?

- Thickness of the steel purlins?

- Are there any trusses involved?

What screws for metal roofing? Choose the correct roofing screws types for the job

1. Should I choose a self-drilling point or a sharp-pointed screw?

Steel purlins or trusses require self-drilling points and timber requires sharp tipped screws.

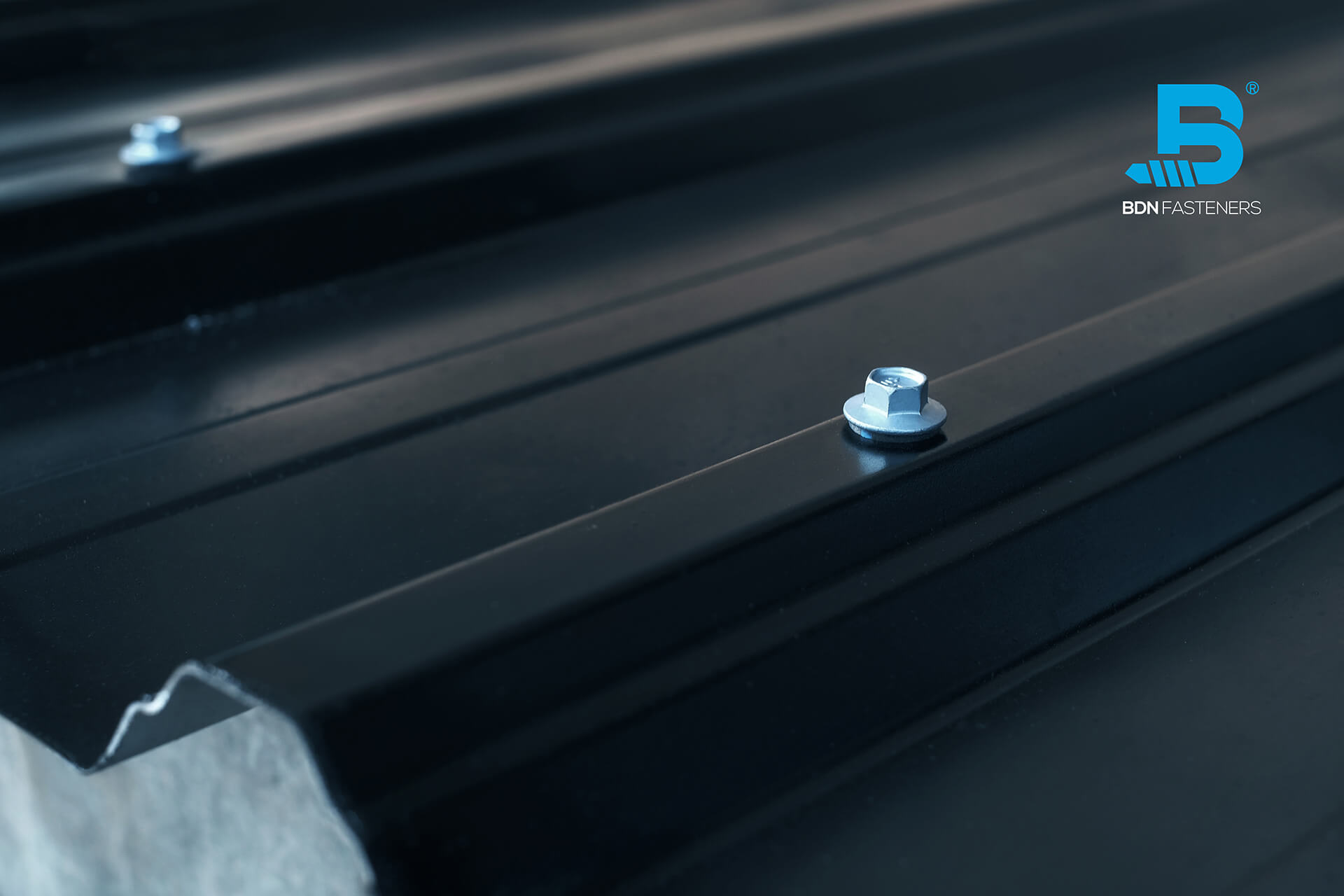

2. What head type does the job require?

Hex profiles are usually the head type of choice for roofing screws, though some may choose a flatter profile which comes with recessed Philips, square or Torx sockets.

3. What screw gauge size does it require?

Screw gauge size, or simply gauge, refers to the major diameter of the screw – the larger the number, the larger the diameter.

Although factors such as choice of wire material, surface, core hardness after heat treatment, and thread pitch and depth are all contributors to the properties of the final product, it is still safe to say that harder and thicker steel, more often than not, require larger gauge screws.

4. What thread count (TPI) should I specify?

Fasteners are often driven first through thinner substrates (i.e. metal roofing sheets), and then through thicker material (i.e. steel purlins or structures), pulling in, and fixing the substrates together.

TPI selection is usually determined by the thickness of the thicker material, though some come with special designs such as a larger diameter upper thread to increase pullout values on a thinner top ply.

5. How long does the fastener need to be?

When selecting what screws for metal roofing, the fastener length should cover the thickness of the sheet plus full height of the corrugation (crest fastening on roofs), and should have at least 2 to 3 full thread penetration on the bottom substrate (i.e. steel purlins or structures).

6. What is the required drilling capacity and choice of drilling tip?

- Drilling tip choice correlates directly with the drilling capacity of a self-drilling screw. Thicker substrates will most definitely require longer drilling tips, and harder substrates normally requires wider tips.

- A reputable distributor or manufacturer should be able to provide sufficient details of the product and its intended use for you to make the correct choice.

7. What category of corrosion resistance coating should I use?

- Understand your environment. For example, areas close to the coast will be at high risk to corrosion due to high salt content in the atmosphere compared to the inland, and therefore would require high weathering resistant fasteners on structures.

- There are multiple choices on the market when it comes to corrosion resistant coatings, and products are normally priced according the number of years the screws can remain rust proof.

Since it is impossible to tell from the naked eye how effective the coatings really are, a reputable company will provide accredited 3rd party test lab reports as proof of compliance.

8. Does it need to be painted?

This normally comes down to personal preference. Some would like head colors to match the roofing sheets, while others simply don’t care.

Paint is another topic which deserves an article of its own, as the weathering process when exposed to the elements sometimes contributes to delamination or chipping of itself and coatings underneath, resulting in catastrophic disasters such as galvanic corrosion in the long run.

9. Do I need a washer? If so, what material should I use?

Washers should be considered an accessory to fasteners, and can be used with or without depending on where it is used. The main purpose of washers is to help prevent leaks and is normally not required for structural applications such as steel truss or frame connections.

- BDN Fasteners has starts out by introducing the all-new Eco-BDN®, green-striped, eco-friendly EPDM Green Washers. Eco-BDN® Green Washers is an optional pre-assembled accessory to our self-drilling and self-tapping screws. These washers provide a perfect seal to the drilled holes and protects it from the elements, whereas the non-conductive feature prevents galvanic corrosion caused by static, while at the same time, being recyclable and bio-degradable.

- Bonded EPDM (ethylene propylene diene monomer) washers offer superior resistance to Ozone, UV, sunlight, are extremely pliable, and highly recommended for use with fasteners.

- PVC washers, though significantly cheaper compared to EPDM washers, are quite stiff, have lower temperature resistance and cannot come in contact with plastic skylights. Due to lack pliability, PVC washers are prone to leakage when used standalone, and should be sealed off with silicone.

Fasteners are normally manufactured according to standards such as AS, DIN, ASTM or JIS to name a few. These standards provide specific sets of rules and regulations, and should be seen as minimum standards on how products should be manufactured. Choosing a reputable brand that adheres to the standards should prevent any unexpected surprises during and after installation.

BDN Fasteners offers roofing screws in multiple sizes and specifications to meet different requirements; BDN Fasteners are all manufactured to Australian AS3566 standards, and backed by matching 3rd party lab reports and real-world testimonials from projects worldwide.

Learn more about roofing screws >>

Impact of metal roof screws rusting & how to prevent the damage

How to choose screws for metal roof installation properly?