Polycarbonate Thickness Chart: Selection and Installation Guide!

When choosing polycarbonate sheets, thickness is key to their performance and suitability. This article guides you on selecting and installing polycarbonate sheets, with the polycarbonate thickness chart providing clear guidance on choosing the optimal thickness.

Polycarbonate Sheet Thickness: What You Need to Know

Polycarbonate sheets come in a variety of thicknesses and range selection from profile to profile, which can be from as thin as 0.4mm to as thick as 15mm or more, depending on the specific product and manufacturer.

Choosing the thickness is the first and most important when it comes to sizing. In general, Solid Flat sheet thickness ranges from 1.6mm all the way up to 15mm, Corrugated profiles from 0.6mm to 2.0mm, Ultra-Thin solid flat sheets, can be made from 0.4 to 1.2mm thick, and Multi-wall polycarbonate sheet thickness can range from 4mm all the way up to 25mm, and with different layers to select from.

For the average consumer, the optimum range for outdoor skylights will be between the 3mm to 10mm range.

Going thinner than 3mm will render sheets impractical outdoors, as the overall setup will be more prone to damage from the elements. Polycarbonate sheets below 3mm are more suited for indoor decoration, partition panels, and areas less prone to outdoor exposure.

Going thicker than 10mm will often be overkill, unless it is aimed at specific purposes, such as heavy-duty industrial applications, sound barriers, or skate rinks, which requires higher impact resistance, as the overall cost of the whole setup would skyrocket.

Key Considerations for Polycarbonate Sheet Thickness

First and foremost, when it comes to polycarbonate sheet thickness selection should be width and length. Width and length should be determined by the maximum wind or snow load and load characteristics of the area, which directly affects how they will be installed. For repairs and replacement of sheets on existing structures, the load-bearing characteristics of the subframe should still be taken into consideration and re-checked.

It is also important for the builder to check if the suggested design conforms to local-building regulations and load-bearing requirements. Most polycarbonate sheet manufacturers or suppliers will be able to provide a thickness and load graph that is formulated using local wind and snow load information provided by the weather bureau.

Moving on to more technical details, contrary to common belief, the strength of polycarbonate sheets barely fluctuates with different thicknesses. For example, the tensile strength of a 2mm thick sheet is around 655 kgf/cm2, while for a 10mm sheet is around 668 kgf/cm2 – less than 2% difference, and the mean impact resistance for both thicknesses exceed 26.67J when lab tested according to ASTM D5628 standards.

The difference between sheet thicknesses does affect the selection of size and method of construction, though what users should really focus on is its flexural strength. One of the main advantages of Polycarbonate glazing material over glass is its flexibility, which also comes with a caveat of sagging if the span is too wide. Ideally, we would like our polycarbonate skylight glazing area to be rafter and purlin-free, without any obstruction of view, though in reality, this could only happen in a gravity-less world.

Comprehensive Polycarbonate Thickness Chart for Different Applications

Below is a general guide of suited applications for different polycarbonate sheet types and profiles, as outlined in the polycarbonate thickness chart.

| Polycarbonate Sheet Type | Thickness (mm) | Application |

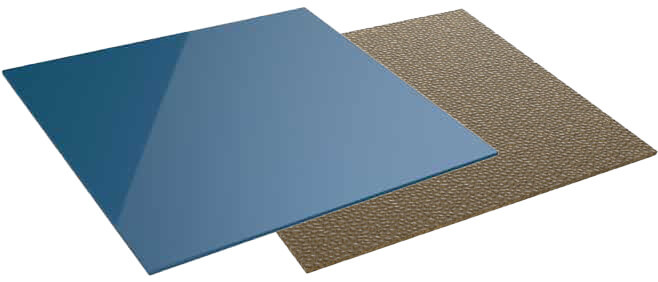

Solid Flat or Embossed Profiles |

2-4 mm | Indoor glazing, picture frames, DIY projects, light covers |

| 6 mm | Greenhouses, skylights, canopies, partitions | |

| 8 mm | Conservatories, pergolas, outdoor roofing | |

| 10 mm | Roofing, carports, verandas, commercial projects | |

| 12mm | Industrial applications, sound barriers, heavy-duty roofing | |

| 15mm | ||

Corrugated Profiles |

0.8mm | Greenhouses, skylights, canopies, pergolas, roofing, carports, DIY projects. |

| 1.0mm | ||

| 1.2mm | ||

| 1.5mm | ||

| 2.0mm | ||

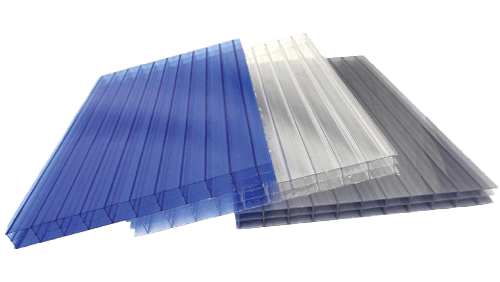

Multi-Wall Hollow Profiles |

2-4 mm | Indoor glazing, picture frames, DIY projects, light covers |

| 6 mm | Greenhouses, skylights, canopies, partitions | |

| 8 mm | Conservatories, pergolas, outdoor roofing | |

| 10 mm | Roofing, carports, verandas, commercial projects | |

| 16 mm | Industrial applications, sound barriers, heavy-duty roofing | |

| 20mm | Large-scale projects, insulated roofing, building facades | |

| 25 mm |

Choosing the Right Polycarbonate Profile for Your Roof Installation

As with any kind of roof glazing installation projects, polycarbonate roof installation involves thorough installation guides as well as meticulous planning and preparation. One of the very first decisions to make is the choice between using Solid Flat/Embossed, Corrugated, or Multi-Wall Hollow profiles. This choice, along with referring to the polycarbonate thickness chart, will determine the installation guide to be used, the type of structure to be built, and accessories required.

Corrugated profiles are suitable for single or multi-panel skylights or side lights in roofs and walls of metal-clad structures such as warehouses. They can also be used independently as roofing or cladding material in arrangements such as agricultural greenhouses.

Solid Flat, Embossed or Multi-Wall Hollow sheet profiles are suitable for single or multi-panel skylights or side lights in roofs and walls of metal-clad structures. They can also be used independently as a roofing or cladding material on Shed, Gable, Hip or Dome type arrangements as on greenhouses, independent frames as on windows or roof skylights, or wet and dry glazing systems as on pergolas, canopies, or sound barriers.

Polycarbonate Sheet Installation: Essential Preparations and Guidelines

A good installation guide should consist of the following information in detail, some of which are very generic to polycarbonate sheets in general, while others differ slightly between Flat, Hollow, and Corrugated polycarbonate sheet profiles.

Pre-Installation Tips for All Polycarbonate Sheets

- Polycarbonate sheets should be transported and stored horizontally on a flat, sturdy pallet whose dimensions are equal to or larger than the sheets themselves.

- Avoid placing polycarbonate sheets directly on rough surfaces or lean against bare walls.

- Make sure that frames are clean and the surface of the insert groove flat.

- Choose a matching thickness for the required bending radius. Though polycarbonate sheets can be cold bent, inner stress still occurs at the bend; external loads accumulated over time must also be taken in consideration when planning.

- Wear safety gear such as gloves and goggles.

- Mark only on the protective film. Use crayons instead of sharp pens or objects to mark on bare sheets.

- Make sure that the UV-protected side of the polycarbonate sheet faces the sun.

- Peel off the masking along the edges of length sides, both sides of the sheet, for about 80-100 mm (3.5-4 in.) from the edges, preparing the sheet for insertion into the connecting profiles or the glazing frame. (Specific to Solid and Hollow sheets)

- Protective films should remain until the installation is completed.

- Remove the upside exterior protective film as soon as the installation of the whole glazed area is completed, or a very short time afterward. Failing to do so, exposing the protective film to direct sunlight may fuse it to the sheet’s face and cause difficulties in removal, due to deterioration of the film, and void the warranty. (Specific to Solid and Hollow sheets)

10 Key Steps for Installing Polycarbonate Sheets

| Step 1. | Leave margin for expansion and depth when inserting the sheets. |

| Step 2. | Use only neutral cure silicone or gasket material for gap-filling. Do not use any PVC materials. |

| Step 3. | Use electric cutters (blades should be made of tungsten carbide). Sheets should be securely fixed to avoid vibration the protective should not be removed while cutting. |

| Step 4. | A minimum slope of more than 5% is recommended, sheets should be installed at pitch rates of 10 percent (1″:10″ slope or 5.7°) or more. If installed at a lower pitch, additional sealing should be applied to insure weather resistance. |

| Step 5. | For multi-panel runs, begin installation of sheets on the side away from wind and rain direction. (Specific to corrugated sheets). |

| Step 6. | Corrugated panels should be installed with the corrugated channels sloping downwards, which will reduce the accumulation of dirt and moisture. |

| Step 7. | Hollow sheets should be installed with the rib channels are sloping downwards. That orientation will reduce accumulation of dirt inside the sheet and ease gravity drainage of condensation moisture. |

| Step 8. | Follow the recommended fastening schedule for each polycarbonate corrugated profile. (Specific to corrugated sheets) |

| Step 9. | Sheets should be installed with the adjoining edges connected by a glazing profile suited to the glazing system. (Specific to Solid and Hollow sheets) |

| Step 10. | Allow for expansion & contraction at fasteners or rabbet depth for insertion type installation. |

Conclusion

Understanding the appropriate thickness for your polycarbonate sheets is crucial for ensuring durability and optimal performance. By referring to the polycarbonate thickness chart, you can confidently select the right sheet for your project, whether it’s for residential or industrial use. For more detailed guidance and top-quality fasteners to complement your installation, visit BDN Fasteners and explore our wide range of products tailored to meet your needs.

Learn more about BDN Fasteners >>

Skylight Leaks When It Rains? Causes and Solutions for Sealing!

Tek Screws for Different Applications: Top Uses and Benefits

Self-Drilling Screws for Metal: 7 Features that Simplify Projects