Metal Screw Types: A Comprehensive Guide to Their Application Introduction

Metal screws are vital components in modern construction, roofing, cladding, framing, and industrial fabrication. Selecting the right metal screw type—based on metal substrate, gauge thickness, head style, drive type, and corrosion resistance—is critical for structural integrity, performance, and longevity.

BDN Fasteners, a Taiwanese manufacturer certified to Australian standard AS 3566, offers a wide array of metal screw types engineered to meet diverse steel‑to‑steel and steel‑to‑timber applications. This guide explores BDN’s product families, technical features, and applications—alongside best‑practice advice for choosing the correct screw.

Metal Screw Types: Self‑Drilling Screws (METAL‑Tite™ Series)

BDN’s METAL‑Tite™ screws are TEK‑style self‑drilling fasteners designed to drill, tap, and fasten in one operation. Made from high‑strength carbon steel (C‑1022) and available in various coatings, they comply with AS 3566.1 for steel‑to‑steel cladding and structural applications.

Key Features

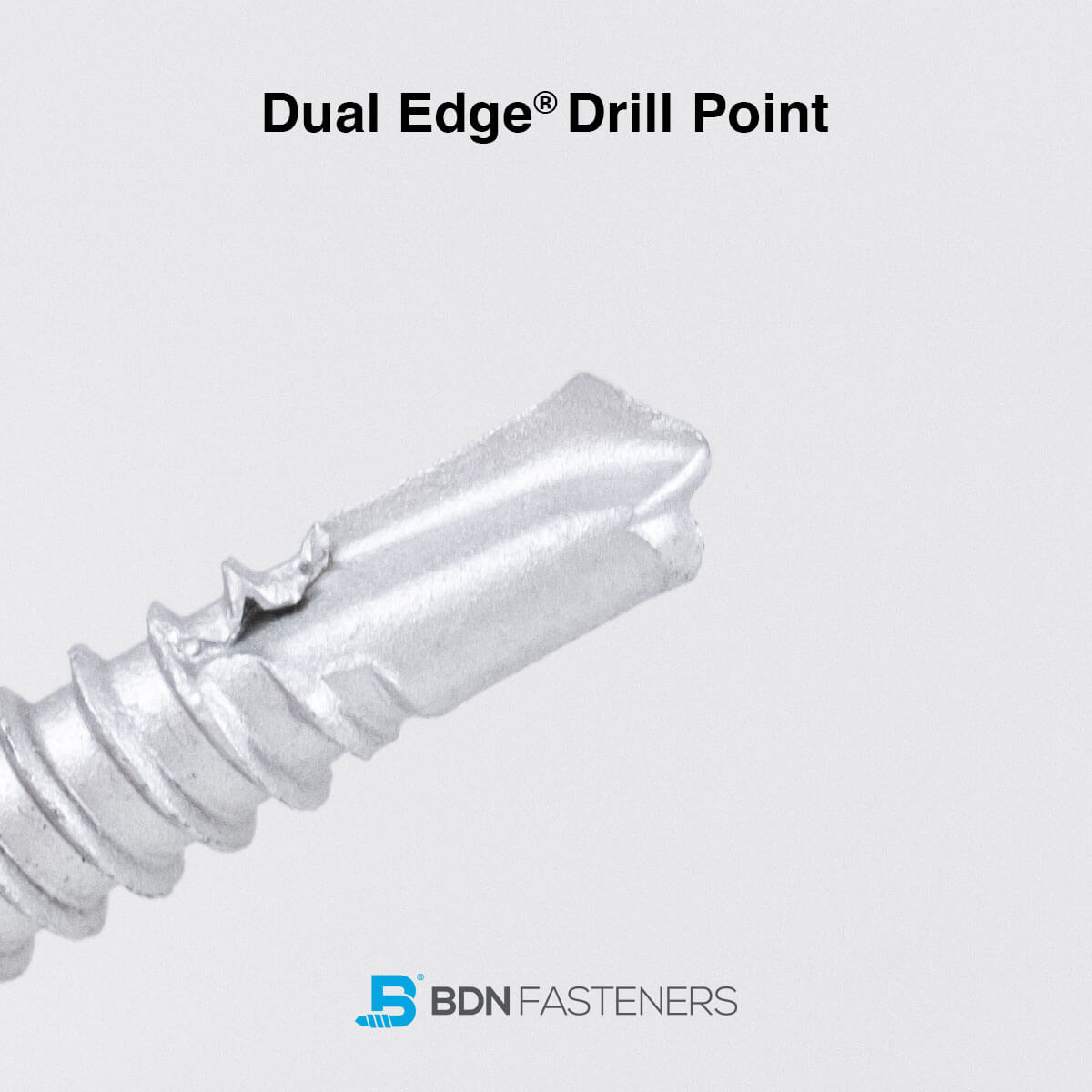

Dual‑Edge® (a.k.a. Thunder‑Shot) Drill Point: Enables fast, clean cutting through steel up to ~4.5–6 mm thick (depending on thread type).

No. 5 Drill Point: Used in heavy‑duty models to penetrate up to 12.5 mm thick substrates, ideal for sandwich panels and thick steel cladding.

Product Variants and Applications

Crest Fixing Fasteners (Double‑Thread #12 Gauge)

Engineered for roof and wall cladding on steel purlins up to 6.0 mm thick. Its upper thread has a larger diameter for pull‑out strength; shank knurls to clear swarf and protect washers from damages.

Standard sizes: 12‑14×50mm, 55mm, 65mm, 75mm, 110mm, 130mm.

Full‑Thread Screws (#12 Gauge Crest Fixing)

Sizes normally start from 45mm, and all the way up to 400mm. Suitable where through‑fixing into support is.

Cladding Fixing (#10 Gauge)

Used for valley fixing lightweight cladding to steel purlins up to 4.0mm thick. Sizes include 10‑16×16mm, 19mm, and 25mm.

Thick Steel & Sandwich Panel Screws

No.5 drill point heavy duty screws such as 12‑24×32mm, 38mm, 50mm handle sandwich panels or thick steel up to 12.5mm.

Stitching Screws

Stitching screws are also called reduced point or needle‑point screws, which are mainly used for lap‑fixing light gauge panels. Screws such as reduced point 15‑15×20mm or needle point 10‑16×19mm are commonly used to minimise thread stripping and provide adequate fixing.

Concealed Fixing Screws

Wafer‑head screws are capable of penetrating up to 4.0 mm thick steel panels, and are normally chosen for its low‑profile and aesthetics.

Common sizes: 10‑24×16mm, 10‑24×22mm

Framing Screws

These screws are specifically designed for fixing steel trusses to plates/beams (~0.75–1.6 mm thick) using trident drill points and high pull‑out strength.

Frame fixing screws (FRAME‑Tite™) with flat top head, e.g. M6.0×22mm, connect studs or lintels to plate, no pre‑punched holes needed

Metal Screw Types: Self‑Tapping Screws

TIMBER‑Tite™ screws are Type 17 self‑tapping screws optimised for steel‑to‑timber fastening, making them an essential option within the wide range of BDN’s metal screw types. They feature:

- Type 17 point for easy thread‑cutting into timber or particleboard.

- Coatings per AS3566.2 for durability.

- Hex or Phillips heads with EPDM washers (e.g. ECO‑BDN® Green EPDM washers for sealing and preventing galvanic corrosion).

They are ideal for cladding over timber battens, purlins, sub-frames or timber-framed structures.

Read more: How to Use Self-Tapping Screws? The Right Way to Install Them)

Metal Screw Types: Specialized Fasteners

Polycarbonate roof fasteners (POLY-FAST™, POLYXPAND™) are designed for fixing polycarbonate solid flat, corrugated, or multi-wall hollow sheets to steel or timber substrates:

POLY‑FAST™ Metal

Self‑drilling screw with built-in 11 mm expansion hole cutter, depth‑stop knurls, domed EPDM washer.

Handles steel substrates up to ~4.5 mm, C4 coating for coastal durability, and saves ~50% labour by combining drilling, thermal expansion hole cutting and sealing in one go.

POLY‑FAST™ Timber (Type 17)

Similar concept but designed for polycarbonate skylight to timber fixation.

These fasteners also come with Domed EPDM washers, recyclable and non‑conductive seals to prevent galvanic corrosion.

Coatings & Quality Assurance

BDN Fasteners offers AS3566.2 compliant coatings to suit different corrosion zones. Coating options include:

- BN3 Class 3 Ruspert Coating for general purpose and standard exposure.

- Class 4 Ruspert or Mechanical Zin-Tin surface treatments for harsher conditions or coastal environments.

Certifications & Manufacturing Control

All products are ISO 9001:2015 and CE certified. Quality control includes in‑house dimensions and drilling performance inspections, along with tests done by third‑party accredited laboratories such as SGS.

How to Choose the Right Metal Screw Types?

Choosing the right metal screw types is more than just picking a size or head style—it’s about ensuring strength, durability, and long-term performance in your project.

With so many options available, from different substrates to coating requirements, it can be challenging to know which screw is best suited for the job. Here are five key points you should consider before selecting metal screws.

Substrate & Thickness

- For lightweight steel cladding (~0.75–4 mm): use #10 or #12 gauge, METAL‑Tite double or full thread screws.

- For structural roof sheeting or thicker steel up to ~12 mm: use No.5 drill point, larger gauge heavy duty screws.

- For thin gauge stitching or lap fix: use stitching fasteners with reduced or needle point.

Fixing Type & Profile

- Crest fixing (through the corrugation crests of corrugated sheet): When fixing to thin gauged metal roofing sheets, it is recommended to choose double‑thread over full thread screws for better pull‑out values.

- Valley fixing: Usually used during wall cladding fixing, it is recommended to use full‑threaded screws.

- Concealed fixing systems: Wafer‑head type screws are usually the head profile of choice for an aesthetic finish.

- Polycarbonate Fixing: use POLY‑FAST™ screws which come with a round Circular Saw for creating an 11mm dia. hole to accommodate thermal expansion, Depth-Stop Knurls to prevent over driving, and a domed EPDM washer to provide the perfect seal against the elements.

Substrate Material

- Steel‑to‑steel: use METAL‑Tite™ self‑drilling.

- Steel‑to‑timber: use TIMBER‑Tite™ T17 (Type 17) self‑tapping screws.

- Timber‑only (e.g., wood sheeting): standard timber screws may be more appropriate.

Corrosion and Environment

- Choose class 4 coated screws for coastal or highly corrosive environments.

- Select Eco‑BDN washers for sealing and electrical isolation to prevent galvanic corrosion.

Torsional Load Strength

Torsional load strength is a measure of how much torque a screw can withstand before it fails by twisting off or breaking. This property is crucial for ensuring screws can handle the stresses involved in tightening and in their intended application.

Below is a table of the minimum torque for torsional strength of different screw gauges according to AS3566 standards.

| newton metres | |||

| Size designation | Torque | ||

| Type ASD | Type BSD | Type CSD | |

| ST 3.5 (No. 6) | 2.7 | 2.7 | 2.7 |

| ST 4.2 (No. 8) | 4.4 | 4.7 | 5.4 |

| ST 4.8 (No. 10) | 5.4 | 6.9 | 7.3 |

| ST 5.5 (No. 12) | 9.4 | 10.9 | 11.3 |

| ST 6.3 (No. 14) | 14.1 | 16.9 | 17.6 |

Case Studies: Real‑World Applications

The best way to see the benefits of choosing the right fasteners is through real-world examples. In this section, we present case studies that illustrate how proper screw selection leads to stronger connections, smoother installation, and more reliable long-term performance.

Roofing & Cladding over Steel Purlins

Use BDN METAL‑Tite #12 double‑thread screws (e.g. SDHCG1255C3N, SDHCG1265C3N) when fixing metal roof sheeting to steel purlins up to ~6 mm thick. The dual thread gives superior pull‑out strength; shank knurls maintain washer integrity by clearing swarf.

Insulated Sandwich Panel Fixing

For thick panels (metal‑insulation‑metal), BDN’s No. 5 drill‑point screws (e.g. SDH5F1238C3N, SDH5F1250C3N) can drill through up to 12.5 mm steel and penetrate insulation/core to secure into backing substrate—ideal for industrial warehouses or cold storage systems.

Polycarbonate Skylight Installation

Use POLY‑FAST™ self‑drilling screws with integrated expansion hole cutter and Domed EPDM washer. These screws create an 11 mm hole in sheet, seal around fix, and prevent crack propagation due to thermal movement—all in one pass. Saves up to 50% labour versus drill‑then‑fix approaches.

Timber Batten Roof Fixing

When metal sheeting fixed to timber battens, use TIMBER‑Tite Type 17 screws sized appropriately (e.g. 10‑12×25mm or 10‑12×20mm) with EPDM washers. Ideal for cladding installations where timber supports are used.

Summary Table: BDN Fasteners Screw Types

| Screw Series / Type | Intended Use | Head / Drive | Drill Capacity | Steel Thickness |

| METAL‑Tite™ (#10 gauge) | Cladding to metal (valley fixing) | Hex flange / dual‑edge | ~4 mm | 0.75–4 mm |

| METAL‑Tite™ (#12 gauge) | Roof sheeting to metal (crest fixing) | Hex flange / double-thread | ~6 mm | up to ~6 mm |

| METAL‑Tite™ (No. 5 point) | Sandwich panels / thick steel | Hex flange / double-thread | ~12.5 mm | up to ~12.5 mm |

| Stitching screws | Side‑lap panel fix | Reduced or needle point | ~2–3 mm | for light gauge sheets |

| Concealed fasteners | Aesthetic flat cladding | Wafer head / PH2+ | up to ~4 mm | light steel profiles |

| TIMBER‑Tite™ (Type 17) | Metal to timber fastening | Hex / Phillips | Self‑tapping into timber | timber substrate |

| POLY‑FAST Metal / Timber | Polycarbonate roof sheeting | Hex flange + EPDM washer | ~4.5 mm steel | handles thermal expansion |

Best Practices and Installation Guidelines

Proper installation is just as important as selecting the right fastener. Following best practices not only ensures reliable performance but also extends the lifespan of both the screw and the structure it supports.

The guidelines below highlight key considerations that help achieve secure, efficient, and long-lasting installations.

- Review Manufacturer Guides and Charts: Always cross‑reference substrate thickness and screw capacity (drill‑point vs material gauge).

- Correct Head & Drive: Match hex flange, wafer head, or frame screws to installation tools and aesthetic requirements.

- Torque Settings: Use variable‑speed hand drills with torque control to avoid over‑driving, washer damage, or substrate distortion. For example, never use an impact driver on screws that are intended for fixing material to steel substrates.

- Washer Integrity: EPDM washers (especially Eco‑BDN) must seat properly; knurls help maintain seal by clearing swarf.

- Coating Zone Compliance: Align corrosion class (3, 4 or above) with environmental exposure and warranty expectations.

Conclusion

Metal screws are not one‑size‑fits‑all components. Correct application demands selecting the right screw series, gauge, head type, drill‑point, and coating—to suit material thickness, substrate type, exposure, and performance requirements.

BDN Fasteners offers a robust lineup—METAL‑Tite™, TIMBER‑Tite™, POLY‑FAST™, FRAME‑Tite™—all meeting AS 3566, backed by ISO‑certified manufacturing, SGS corrosion testing, and thoughtful innovations such as dual‑thread, trident points, and Eco‑BDN washers.

By understanding these product types and pairing them correctly with project demands, specifiers and contractors can achieve strong, corrosion-resistant, fast installations—ensuring structural integrity, visual quality, and long-term performance.

If you need technical support or have product inquiries, contact BDN Fasteners today to find the right solution for your project.