How to choose screws for metal roof installation properly?

The majority of BDN self-drilling screws are designed for either metal roofing or wall cladding installations, with the exception of proprietary designs for specific purposes such as PolyXpand™ for plastic skylight fixings, or TRUSS-Tite™ for joining truss components on steel framing.

Common issues we see on high quality, expensive metal roofing sheets fixings are:

- Incorrect selection of screws, with issues ranging from length, drilling capacity, thread type, gasket, and more.

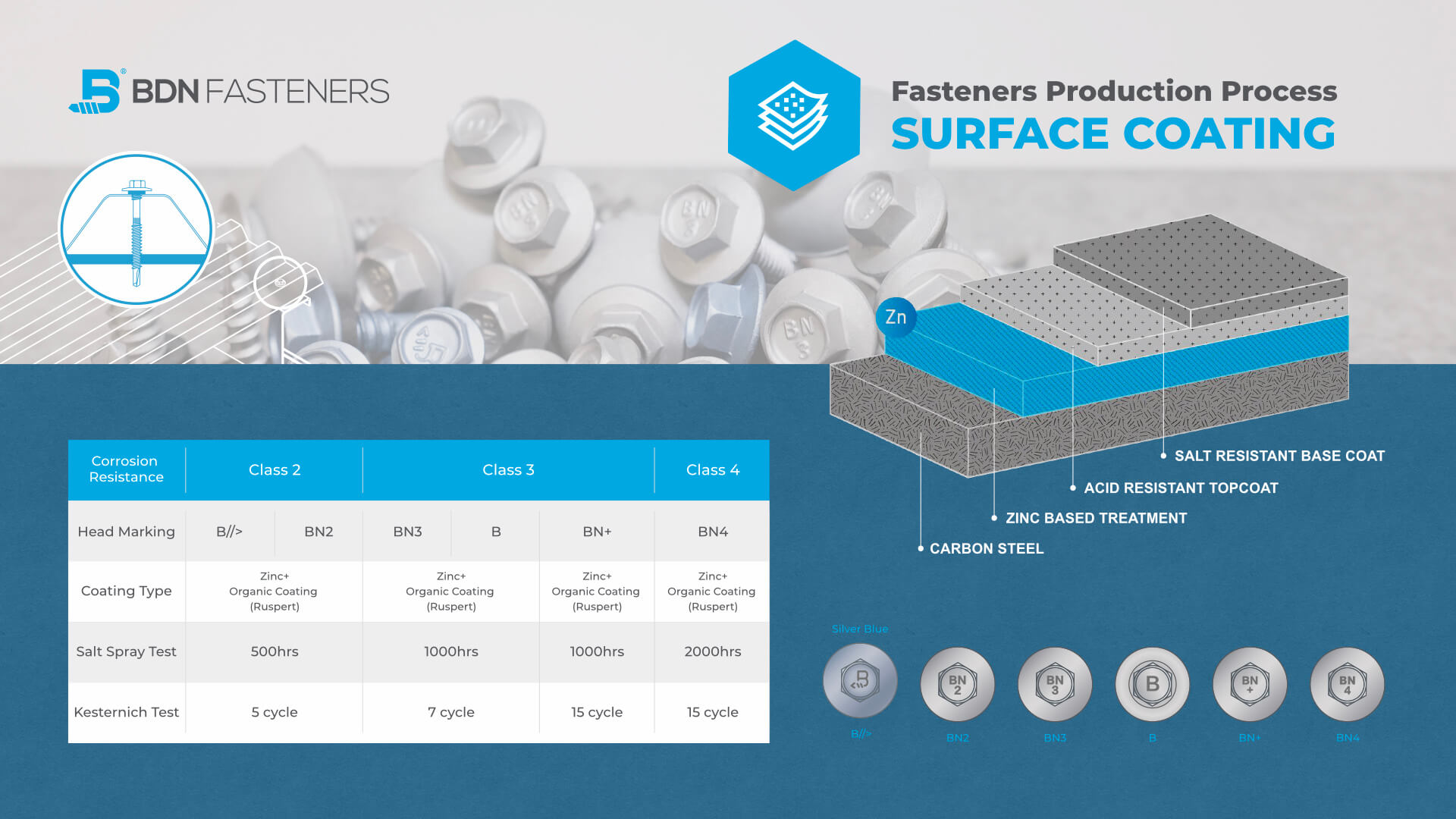

- Poor quality screws which are unfit for the location and environment installed in.

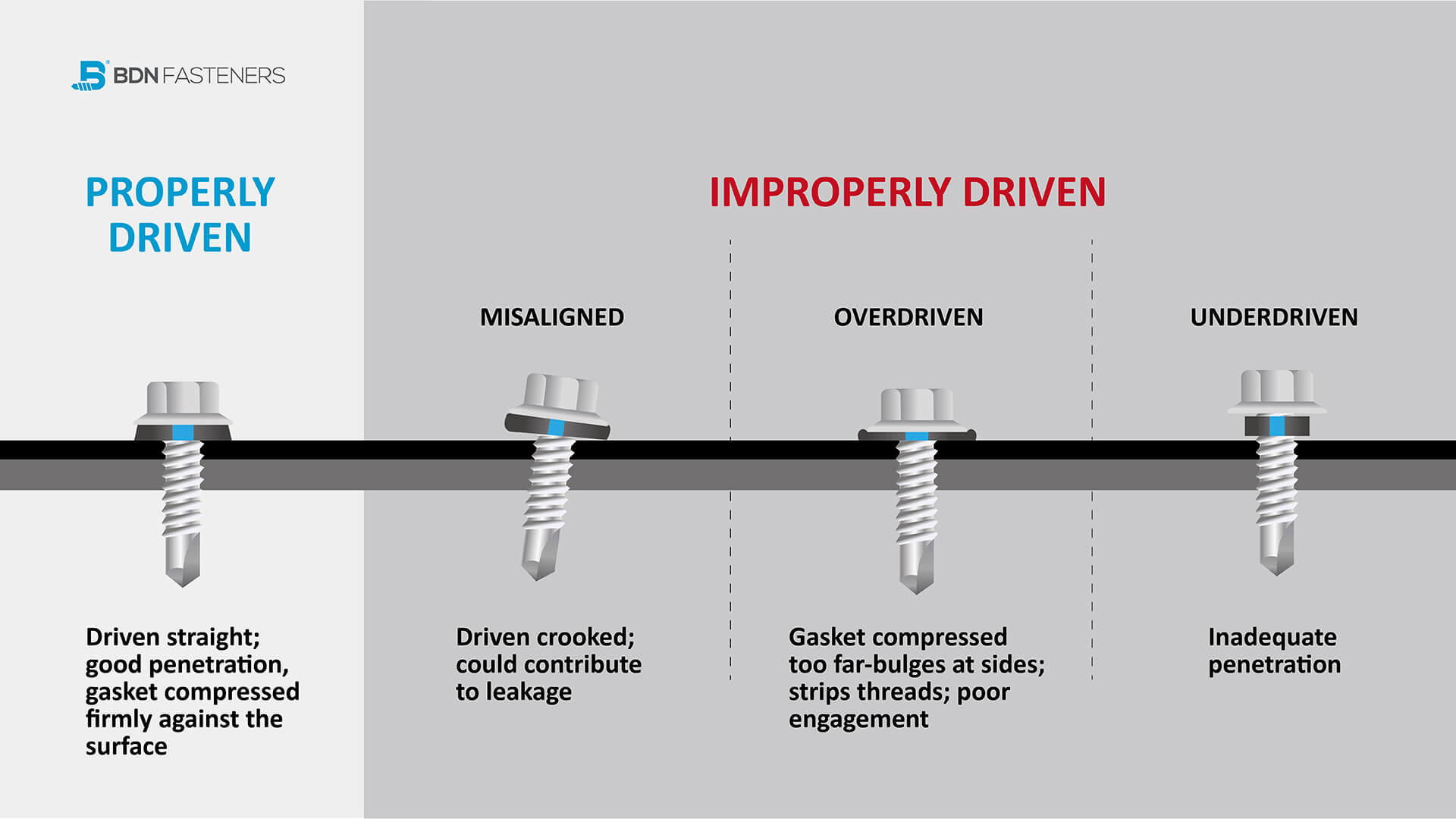

- Improper screws for metal roof installation – the majority of issues stem from insufficient knowledge of the product, not following installation guides and instructions, and most of all, carelessness. Don’t forget that choosing the correct tool for the job also plays an important part in proper installation.

Before any installation, understand the type of structure, material, and environment we are dealing with. Since we are talking about screws for metal roof installation, determining the type of metal roof will be first priority.

- Is it a single sheet insulated panel?

- Are there any skylight panels installed in between sheets, and if so, what type of material are the skylights?

- What is the thickness of the sheet, and how thick is the insulated portion underneath?

- Color of the sheet and should the screws have to come with matching head colors?

Upon determining the type of sheet used, we then have to understand the type of structure it is affixed to.

- Are the purlins steel or timber?

- Thickness of the steel purlins?

- Are there any trusses involved?

We should then determine the kind of environment the building structure is built on. Here at BDN Fasteners, we have categorized the kind of environments to the following based on its characteristics. Scope of warranty for our products are also based on the category the environment is classified to.

Dry, Rural Areas –

- Areas remote from the coast and sources of pollution; as well as all of the areas listed below.

Mild Urban or Rural Areas –

- Areas with little to no chemical pollution, including but not limited to natural chemicals such as ammonia from livestock or carbon monoxide from log-fire.

- Areas far from the coast with no impact from salt water spray.

- Areas at least 2 kilometers away from any type of industry, light or heavy.

Light Industrial or Urban Areas –

- Light industrial zones, light manufacturing, warehousing, distribution, or limited light intensity activity areas.

- Built up areas constituted of high human population and infrastructures.

- Areas at least 1~2 kilometers away from light industrial or urban areas.

Small Industrial Zones –

- Areas located in or adjacent to small industrial zones.

Coastal Areas –

- Areas located approximately 2 kilometers from the coast.

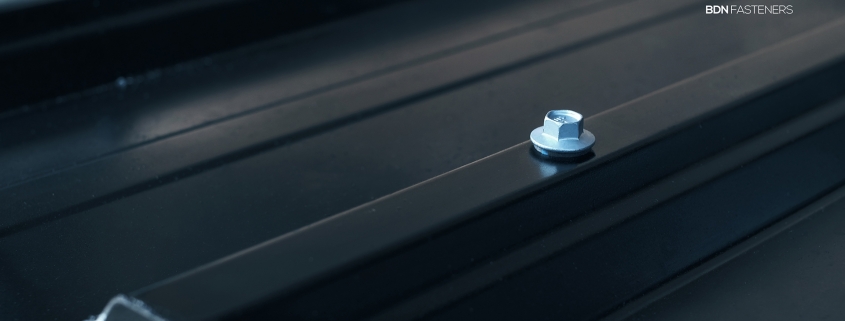

Lastly, choosing the correct screws for metal roof installation is only half the job done, and it all comes down to how the installer completes the final touch, as an improperly installed screw is worse than none installed at all.

Above are basic guidelines for the novice builder or contractor to follow when making the correct fastener selection. Since building sites differ from one another, additional factors may be required to take into consideration; it is best to contact an experienced salesperson or technician for on-site checks before making final decisions.

Learn more about BDN Fasteners >>

Internal Roof Insulation Installation with Self-Drilling Fasteners

How to use self tapping screws for metal?