Green House Roof Materials: Why Polycarbonate Is the Best?

When it comes to green house roof materials, polycarbonate stands out as the best option due to its durability, light transmission, and insulation properties. This article will explore why polycarbonate outperforms other materials like glass, polyethylene film, and fiberglass reinforced plastic (FRP), focusing on its ability to withstand harsh weather conditions while providing excellent light diffusion and thermal insulation.

You’ll also find insights into the advantages and potential drawbacks of various green house roof materials, helping you choose the most suitable option for your greenhouse.

The 6 Most Common Green House Roof Materials: Pros and Cons

Below is a list of common green house roof materials with their pros and cons:

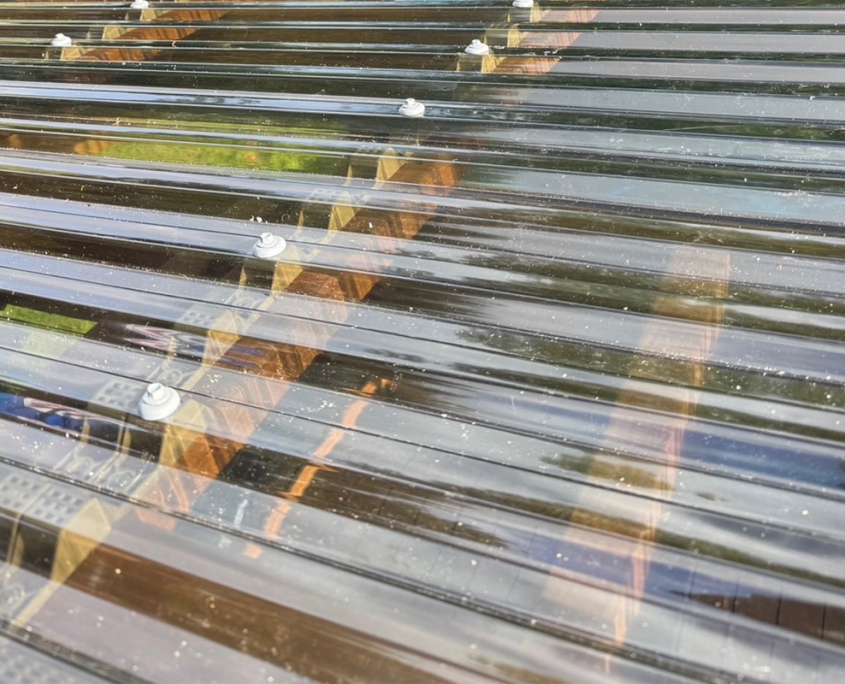

1. Polycarbonate:

Types:

- Available in single, twin-wall, or multi-wall sheets. In general, single layered, corrugated profiles have better reflective and refractive properties, whereas multi-layered profiles provide better thermal insulation properties.

Advantages:

- Durable and Impact Resistant: Virtually unbreakable, polycarbonate is one of the most durable green house roof materials, capable of withstanding harsh weather conditions like hail, heavy snow, strong winds and vandalism.

(Read more: Wind Resistant Greenhouses: Guidelines for High Wind Areas!) - Good Light Transmission: Clear polycarbonate sheets have a visible light transmission rate of around 88% and up to more than 90% percent with additional layers of coating. Visible light transmission rate can be lowered to the point of even becoming diffused or translucent either mechanically with special tooling during the extrusion process, or with special additives that are included within the polycarbonate masterbatch.

Multiple layering such as Twin-wall or multi-wall options can also provide even light diffusion. The aforementioned PC sheet types and methods are all aimed towards changing the characteristics of sunlight to match requirements. - Insulating Properties: Provides good thermal insulation, helping maintain a stable temperature. This can also be done by using multiple-layered sheets or single layered sheets that include infrared blocking/reflecting properties.

- UV Protection: Comes with UV-resistant coatings to protect not only the sheets itself, but also the plants or living organisms underneath from degradation.

- Lightweight and Easy to Install: Easier to handle and install than glass, and on par with other plastic glazing materials such as uPVC, PVC, Acrylic, or Fiberglass.

(Read more: How to Build a Green House? Expert Instructions and Insider Tips) - Cost-Effectiveness: While polycarbonate in itself has a higher initial cost compared to other plastic glazing materials such as PVC, Fiberglass or PE Film; its durability, lower maintenance, and energy efficiency makes it very cost-effective in the long run. The advantages of PC over other plastic glazing materials totally offsets the cost disadvantage. Keep in mind that the structure required for plastic glazing material is very similar.

Disadvantages:

- Initial Cost: Higher initial cost compared to materials like polyethylene, but significantly lower compared to glass, which is a lot heavier and requires stronger structures to support.

- Aesthetic: Polycarbonate sheets are more prone to scratches compared to glass and more prevalent on clear sheets. PVC and Fiberglass are quite translucent in itself for scratches to be as visible. Although Acrylic has identical scratch resistance as polycarbonate when untreated, light scratches can be removed through polishing.

2. Glass

Types:

- Single or double-glazed tempered glass.

Advantages:

- Excellent Light Transmission: Allows up to 90% of sunlight to pass through, making it one of the top green house roof materials for plant growth.

- Aesthetic Appeal: Offers a classic, attractive look for greenhouses.

- Longevity: With proper maintenance, glass can last for decades.

Disadvantages:

- Fragility: Can break or shatter under impact from hail, debris, or strong winds. Tempered glass can be more impact resistant, but it comes at great additional cost and less ideal for budget constrained projects.

- Heavy and Requires More Skill to Install: Requires a sturdier frame and professional installation.

- Poor Insulation: Less effective at retaining heat compared to polycarbonate or polyethylene.

3. Polyethylene Film

Types:

- Available in single or double layers (air between layers provides insulation).

Advantages:

- Affordable: Its low initial cost makes polyethylene one of the most affordable green house roof materials, popular for both small and large greenhouses.

- Good Light Transmission: Provides adequate light for plant growth.

- Flexible and Lightweight: Easy to install and replace.

- Improved Insulation: Double-layer options offer better heat retention.

Disadvantages:

- Short Lifespan: Typically lasts 2-5 years before needing replacement.

- Prone to Tearing: Can be damaged by strong winds, sharp objects, or heavy snow.

- UV Degradation: Degrade and yellow over shorter periods of time even when treated with UV inhibitors.

4. Acrylic

Advantages:

- Good Light Transmission: Allows for up to 90% light transmission, similar to polycarbonate and glass.

- Durable: More impact-resistant than glass, but still cracks and shatters not gone through special surface treatment. Sheets that are not produced with virgin material have less physical strength and lesser properties.

- Lightweight: Easier to install than glass and comparable to polycarbonate.

Disadvantages:

- Brittle: Can crack under impact or with age, especially in cold climates.

- Expensive: Higher cost than polyethylene and comparable to polycarbonate, though some may add a mixture of melamine during production to save costs.

5. Fiberglass Reinforced Plastic (FRP)

Advantages:

- Light Diffusion: Excellent light diffusion, which is beneficial for even plant growth.

- Durability: Resistant to weathering and can last up to 10-15 years.

- Moderate Insulation: Provides some insulation, better than glass but less than multi-wall polycarbonate.

Disadvantages:

- Fading and Darkening: Colour fading or darkening without loss of gloss can be due to the use of unstable pigments or pigment combinations which change colour after exposure. This can be mitigated by the appropriate choice of pigment.

- Yellowing: Yellowing is a sign of brittleness and due usually to the darkening of the base gelcoat resin, especially in whites. This can be overcome by using a more UV-resistant resin and better UV additives, and by ensuring good cure of the resin. Surface Coatings also provide protection.

- Blooming: Blooming is caused by migration of an incompatible pigment or additive to the surface of a gelcoat to give a mat, faded appearance.

- Loss of Gloss and Chalking: Loss of gloss is normally brought about by erosion of the surface layer of the gelcoat due to chemical and/or physical damage.

- Moderate Cost: Generally more expensive than polyethylene but less costly than glass.

6. Shade Cloth or Netting

Types:

- Made from materials like polypropylene or polyethylene mesh.

Advantages:

- Temperature Control: Provides shade and reduces internal temperatures, which is ideal for hot climates.

- Flexible: Can be used temporarily or seasonally.

- Affordable: Cost-effective and easy to install.

Disadvantages:

- Limited Protection: Does not offer insulation or protection from rain or snow.

- Reduces Light Transmission: Cuts down on the amount of sunlight entering the greenhouse.

Choosing the Right Green House Roof Material

The best Choosing the Right Green House Roof Material depends on several factors, including climate, budget, the types of plants grown, and the desired lifespan of the covering. For long-term durability, polycarbonate and glass are excellent choices, while polyethylene film is a cost-effective option for temporary or seasonal use. To find high-quality fasteners and accessories for installing your greenhouse roofing, visit BDN Fasteners.