This is a question often brought up by DIYers, usually when trying to fix a broken piece of furniture, rebuilding part of a decking platform, or simply rejoining two pieces of wood that have somehow come loose with time – an age-old debate that started from before our time and continues until this day.

Both methods have proved its worth having survived for centuries, though none more so than the other, and we believe that it is down to choosing the best method to suit your needs.

When done manually, the difference in speed and precision between nails and screws installation was quite obvious. Nails were easier and faster to drive but had less precision, and screws offered pinpoint precision but was slow and laborious. However, the advancement of pneumatic and electric power tools for nail guns and screw guns have rendered the comparison pointless, as the tools made installation a breeze.

If speed and precision is out of the equation, one might wonder what else is left to compare? As a fastener manufacturer selling under our own brand name, it is imperative we provide accurate information to our customers. The choice between nails and screws of the same caliber all comes down the Shear strength, Tensile Strength, and Holding Strength.

- Shear Strength: The shear load required to break the screw, the ability to resist the pressure of two joined pieces “sliding” past each other.

- Tensile Strength: The tensile load required to break the screw, the ability to resist being pulled part, breaking under pressure.

- Holding Strength: How well the jointed substrates hold up against each other.

Nails tend to have better shear strength compared to screws, which means more flexibility, a very important feature suited for structural joining, framing, exterior wall sheathing, or hardwood floor installation. Nails made with correct materials will bend to a large angle and less likely to snap compared with screws.

Screws are better for delicate jobs and because the installation process involves less vibration, does not mar the surface, are easy to remove, and can be installed with precision. The tapping process during installation creates a tighter bond when reusing the original nail hole.

To summarize, use nails when joined surfaces are more likely to slide, and use screws for joined area which are more likely to pull apart, and on holes that previously had nails in them.

What defines a strong screw, and can be categorized among the strongest screws for wood? Answers may vary, as the versatility is based on the application and its intended purpose.

Screws for wood can be used for smaller jobs such as joining cabinet and furniture parts, mounting hardware or accessories, or simply connecting parts. In the past, simple, old fashioned slot recessed screws were used but can easily fail during the drill drive process due to the slot unable to handle larger torque from electric hand-tools, and was replace by either Philips, Square, or Torx drives.

For timber framing, log home building, mass and heavy timber construction however, larger diameter structural timber screws are used and require a totally different set of mechanical properties, test standards among other differences.

Wood, as with all organic materials on planet Earth, is unique in a way that though we are able to tell between different types of wood from its texture, none of the fibers are identical, meaning the composition in relation to strength varies, which is the main challenge when designing a strong screw. Below are main areas to look out for when designing strongest screws for wood.

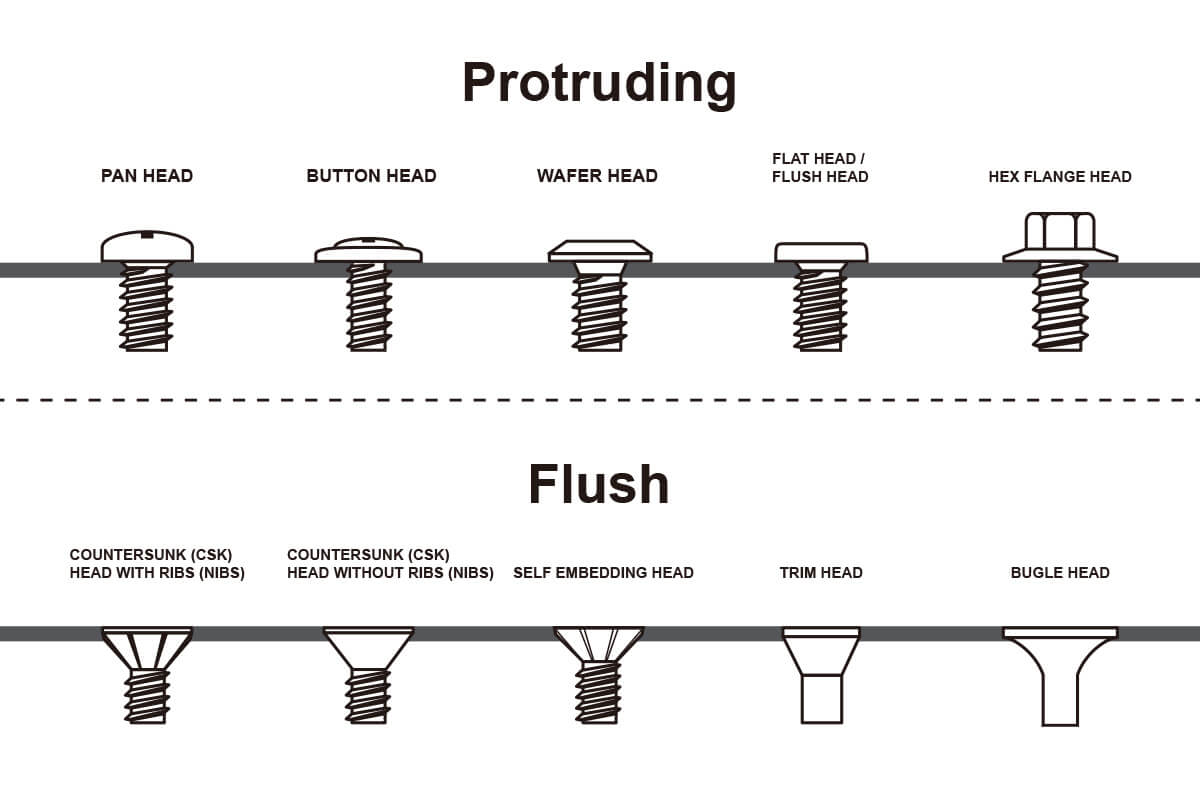

Head type – Flush or Protruding

Regardless of gauge, thread, or length, screws for wood come in all kinds of head types, though they can mainly be divided into two groups, one that sits flush against the surface, the other which protrudes and stands out. Neither is superior to the other, and the choice depends on the application.

Heads that sink flush against with the surface are normally chosen when used standalone to join other pieces of wood, such as decking or when no protrusion is allowed such as fixing door hinges to wooden framing. Doors wouldn’t be able to close properly if screw heads were protruding from the holes. Depending on the screw gauge, heads that sink flush or sits flat normally have smaller heads with less contact area, and better suited for which does not require great holding force.

For outdoor applications such as fixing metal roofing sheets or wall cladding sheets to wooden purlins or frames, head types such as BDN’s hex washer flange head that sits tall against the surface, will withstand much more drive-in torque compared to flush and countersunk type heads which has the potential of breaking under heavy torque due the recessed drill and drive system.

A very common design among flush or protruding threads is the addition of nibs underneath the head to either create a perfect countersunk hole and extra grip to prevent slippage.

Screw gauge to head size ratio – Increased screw diameter also requires increase in its washer head diameter to provide adequate holding strength

Thread design

As mentioned above, natural wood fibers differ in texture, grain, and vary in hardness; a properly made thread should pierce through the surface of the wood, pull the screw in without creating any splits or splinters, while hold itself and the joined substrate firmly without fail.

Common knowledge among woodworkers has been fine threads for hardwoods, and coarse threads for softwood, though through improvements in thread rolling machinery, dies and computer aided design, threads have become more sophisticated and specialized to included knurls, hi-lo threads, cross cutting, serrated edges among others.

Drill Point

Eliminating the pilot-hole drilling process when drilling through timber wood saves a huge amount of time and labor but does come with caveats. Though technically not as complicated compared to self-drilling screw drilling points, a good sharp point design is still critical in the strongest screw for wood competition.

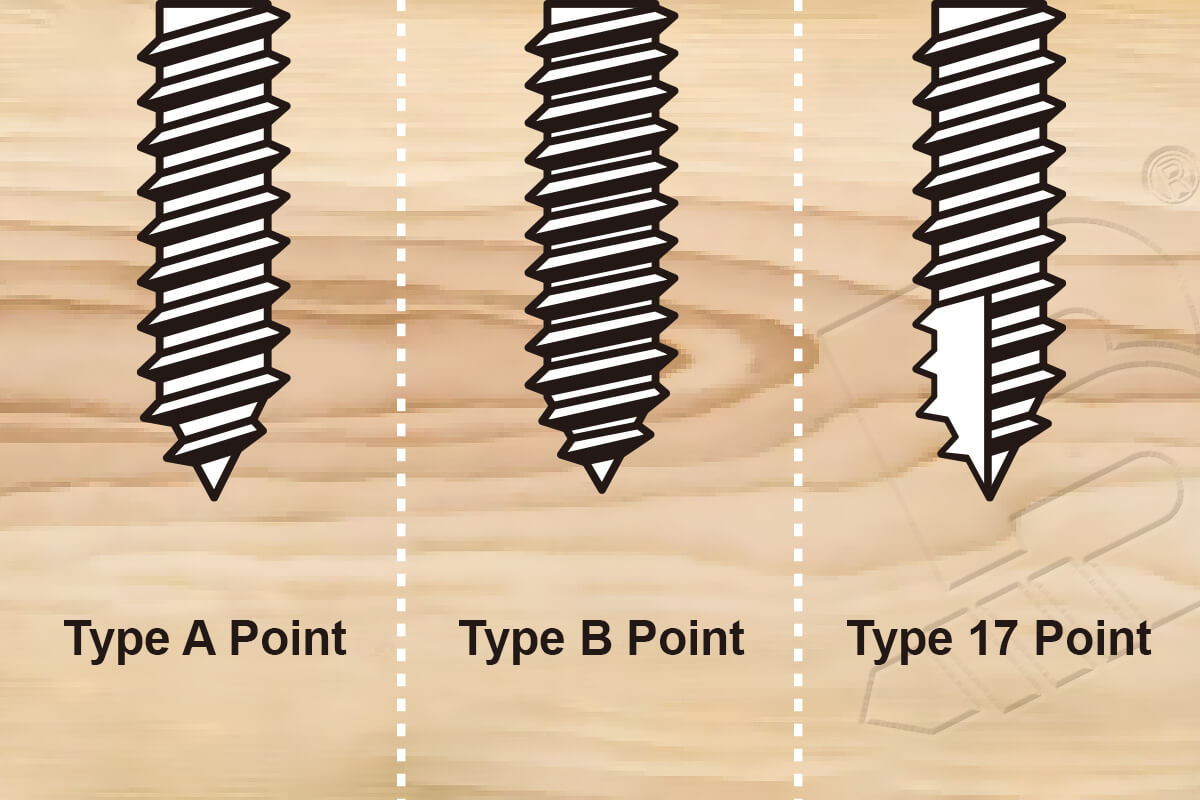

The perfect sharp timber screw point should quickly penetrate wooden surfaces and create perfectly sized entry holes for the threads to follow through. This would normally require features such as BDN TIMBER-Tite’s proprietary Type 17 Sharp Point, which is not only sharp, but has self-tapping flutes to clear off sawdust, allowing fast and smooth operation.

BDN Fasteners offers an extensive range of premium quality self-tapping and self-tapping timber, drywall, and decking screws for timber to timber or steel to timber applications. For more information, contact us through email or a simple phone call today.

Recommended Reading: TIMBER-Tite™ Self-drilling timber screws

When deciding what screws to use for metal roofing, it is important to understand the choice of metal sheet material and available options, and also check its compatibility against the environment, and if complies with local building regulations. Many might see their choice limited by budget or price sensitive biddings, though it is always wise to think ahead see things in a broader sense.

Below is a simple checklist that will determine the type of screws to use for metal roofing.

- Sheet material and thickness: This will determine the gauge, and drilling tip type. The thicker the sheet, the larger the gauge, and longer the drilling tip.

- Sheet color: This will determine whether or not to go for painted head screws and the matching color.

- Measurements of the profile: Water always finds its way to the lowest point, and it is imperative to avoid creating holes at lower areas of sheets. Which means that screws should always be fixed at the corrugation crest of any metal roofing sheet. The height of the corrugation will determine the screw length required.

- Is it an insulated panel? If so, what is the thickness of the insulated portion? – The insulation thickness will determine the screw length required.

- Will there be skylight panels involved during installation? – Skylight panels and metal roofing sheet when used in combination, is a totally different breed. Skylight panels can be installed as single panel or multi-panel runs, or framed independently of the metal sheets, all of which require different overlapping methods and fixtures.

- Purlin and Truss material: Self-drilling screws are required for steel purlins and trusses, and sharp-tipped screws are required for timber. There is also screws that are designed to do both, such as the BDN DUAL-Tite™ 2-IN-1 roofing screws, suited for hard timber and up to 3mm light metal fixing.

- Corrosion resistance coating: Areas close to the coast will be at high risk to corrosion due to high salt content in the atmosphere compared to the inland, and therefore would require high weathering resistant fasteners on structures. For rural areas, inland, or indoors, the demand for high corrosion resistant screws will be less.

The cost of screws is normally a fraction of the whole metal roofing setup, but is detrimental to the lifespan and safety of the covered area. Roofing sheets have to hold up against rain, wind, and shine to protect what is underneath, and screws are what keeps substrates securely fastened. There will always be cheaper alternatives when it comes to building materials, though at what cost? Short-term savings at the risk sacrificing safety and stability is never a good choice in the long-term.

Further Reading: Step by step tutorial on choosing the correct roofing screw types