Tag Archive for: FAQ

Types of screws for metal installation, BDN Fasteners has developed 9 types of screws for metal which are split into 5 categories for you to choose from.

The Origin of Screws

BDN Fasteners specializes in manufacturing self-drilling and self-tapping screws, and a wide selection of types of screws for metal fixing.

Although the origin of screws is up for debate and was known to be used as early as the first century B.C., and has evolved to a plethora of length, sizes, and specific usage, the basic function has remained to be affixing two objects together, securely.

BDN Fasteners

Due to the ever-changing building regulations and codes which also differs from country to country, BDN Fasteners have developed 9 types of screws for metal which are split into 5 categories.

Regardless of the design and purpose these screws are aimed for, BDN Fasteners for metal include basic and proprietary designs which are manufactured to the highest standards, no corners cut.

- Basic Designs –

- Mechanical Properties – Follow AS3566 standards for Self-drilling screws for the building and construction industries.

- Corrosion Resistant Properties – Surface coating designed to withstand the elements and can be adjusted to cope with specific weathering conditions.

- Proprietary Designs – Specific designs offer unique properties that provide superior performance for all BDN types of screws for metal.

- Trident Drill Point (Pat.) – Provides fast, steady and pinpoint precision drilling performance, effectively clears swarf and drills through 6mm thick steel.

- “S” Swirl Drilling Tip – Creates a larger area of engagement from the initial drill drive.

- Improved “Cutting Edge” Design – Larger, curved cutting blade edge lower manual load required.

- Scratshank / Double Scratshank – Effectively cuts and break out metal filings around the drill hole, keeping it free of damage to sealing washers during installation.

Types of Screws for metal

|

The types of screws for metal include but are not limited to the following series: |

|

|

METAL-Tite™

|

|

DUAL-Tite™

Duofix 2 IN 1 Roofing Screw for Fixing Roof Sheeting to Light Metal and Timber. |

|

TRUSS-Tite™

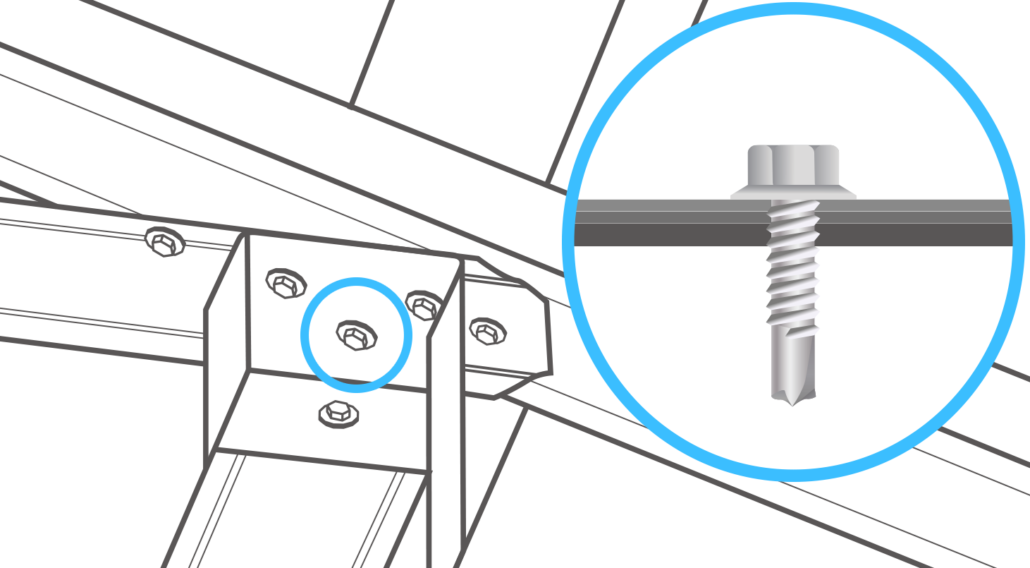

For the assembly of metal truss components through pre-punched holes. |

|

FRAME-Tite™

Flat topped frame screw designed for stud to plate connections and connection lintels to plate without pre-punched holes. |

|

POLYXPAND™

Fixing Polycarbonate Sheeting to Metal. Offered in Crest Fixing and Valley Fixing screws for metal versions.

|

|

POLY-FAST™

Features a fail-safe thermal expansion hole cutting washer design for fixing Polycarbonate Sheeting to Metal. |

For more information on BDN types of screws for metal, please contact the dealer near you, or send us an email at info@broadenal.com.tw.

Learn more about BDN Fasteners >>

Are screws recyclable? Two stages of screw recycling process.

What are self-tapping screws used for? BDN Fasteners shall explain 2 different types of self-tapping metal screws and what are self-tapping screws used for.

What is a Self-tapping Screw? What are Self-tapping screws used for?

To begin with, self-tapping screws, as its name suggests, is a screw capable of tapping threads and securing various types of materials such as wood, metal, plastics, drywall, bricks, cement and so on and so forth.

It is not to be confused with self-drilling screw in that self-tapping screws usually come with a pointed tip instead of an integrated drill bit, meaning that while being able to drill through thin gauged metal sheets, though on thicker material, it normally requires pre-drilling a pilot hole.

2 Different Types of Self-Tapping Screws

Self-tapping screw threads come in two different types: forming or cutting.

Thread-forming means that threads are formed over the course of drilling into the material, with softer materials such as plastics being the most common.

Thread-cutting types are mostly used on metal, wood, bricks; which requires threads to “cut” into the harder material for an adequate fix.

As with all screws, especially ones that self-tap threads onto material, it is imperative to not apply too much pressure during the process, and take extra care to follow the same track when disassembling or re-assembling the screws to avoid stripping.

What are Self-tapping screws used for?

What are self-tapping screws used for you may ask? Although self-tapping screws usage varies from country to country, they are mainly used for securing single or double layers of thin gauge sheet metal (which is the reason why people also call it sheet metal screws), fixing brackets into wood, fastening aluminum sections to each other, drilling into plastic housings or plastic plugs.

Learn more about BDN Fasteners >>

How to use self tapping screws for metal?

What’s the Difference Between Self-Drilling and Self-Tapping Screws?

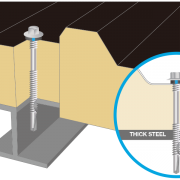

There will come a time when you will encounter a seemingly impossible task, a piece of steel so thick and heavy duty that even your already awesome BDN No.3 point TEK screws in the toolkit cannot handle. There will come a time when you the piece of steel in front of you may be tagged as “mild steel”, but in fact is composed of complex, unevenly distributed alloys, which creates a big challenge for regular self-drilling tips, and almost impenetrable.

One of the most important job a self-drilling screw has to muster, is clearing out excess material, or swarf, while drilling. Having a hardened drilling point and sharp cutting blades only helps with the initial drill and drive, but without a flute long enough and designed correctly to bring out the excess during the spiraling action, iron shavings left in the hole are heated easily from all the spinning, causing the drill to burn out. Once this happens, there is little to no chance of penetration with the screw, and you’ll have to start all over again.

A lot of big brand names are marketing their screws as either self- as TEK screws for thick steel, heavy duty self-drilling metal screws, or self-drilling screws for thick steel, capable of drilling through 12.5mm steel and above, though not many can perform as advertised.

Not for BDN METAL-Tite™ Heavy Section Fasteners. Ours perform flawlessly, without fail.

BDN METAL-Tite™ heavy section, penetrates 12.5mm thick steel with ease. The patented Thunder-Shot drill point prevents wandering during the initial drill drive, clears out swarf swiftly and efficiently. The whole screw is coated with BN3 silver coating, which consists of multiple layers of specially formulated, corrosion resistant chemicals, and can easily withstand 1000hrs of salt spray test (ASTM B117), and 7 Kesternich cycles (DIN50018 2.0 SFW).

BDN METAL-Tite™ heavy section screws are also offered in a special 16mm thick steel penetration version. Designed to not only drill through thick, hardened, or complex alloy steel, but can also pass stringent 1mm + 2mm + 9mm, and 2mm + 12mm penetration tests. The most demanding part of these two tests is to withstand the impact force on the drilling tip when it passes through the first and/or second sheet, and hits the final thick hardened layer of steel. Imagine the wear and tear, plus heat buildup of the drilling tip during the first and/or second process. Nevertheless, BDN Heavy duty self-drilling metal screws pass these two stringent tests with flying colors.

Please contact your nearest BDN Fasteners dealer for further information.

In light of recent rumors from certain companies declaring affiliation

with Tai-One Enterprise or BDN Fasteners®, we hereby announce:

- Tai-One Company is the sole authorized agent and distributor of BDN Fasteners® in Thailand and in no way affiliated with other brands and products.

- BDN Fasteners® is a trademarked brand in both Taiwan and Thailand.

- All of the BDN Fasteners® branded products sold by Tai-One Enterprise are manufactured, packed, quality checked, and imported directly from our factory in Taiwan. BDN Fasteners® Taiwan holds all of the patents, intellectual property rights and export records to be provided upon request should the need arise.

- All BDN Fasteners® goods imported by Tai-One Enterprise are legally compliant with the Thailand import rules and regulations; while all sales and services are VAT invoiced and provided to customers.

We thank you for the trust and support of Tai-One Enterprise and BDN Fasteners®. Kindly call us for more information and verification should you hear any rumors that differ from this announcement.

Tai-One Enterprise & BDN Fasteners® hereby declare the above information are true and correct.

Internal roof insulation

Thermal insulation, which is required mainly for homes in order to slow down the flowing in or out of heat, is often added to walls, roof, ceilings, or floors. As heat primarily escapes through conduction or physical contact with the colder temperature outside, construction and insulation of walls and roofs are crucial to keeping heat inside.

For buildings that were built with poor roof or wall insulation, remodeling could become a big burden, which usually involves taking off of the original roofing panels, and purchasing new insulation panels.

Steel sandwich panels are among the most commonly used material for building either industrial, commercial, agricultural, or public domains. Sandwich panels can often be tailored to suit various thermal, acoustic or strength requirements by combing layers of different materials in different thicknesses to achieve the desired effect.

As mentioned in our other article: Step by step tutorial on choosing the correct screw type for roofing applications, it is important to understand and choose the correct screw type of the job. BDN Fasteners offer a complete fastening solution which consists of various screw types for your insulated roofs or walls.

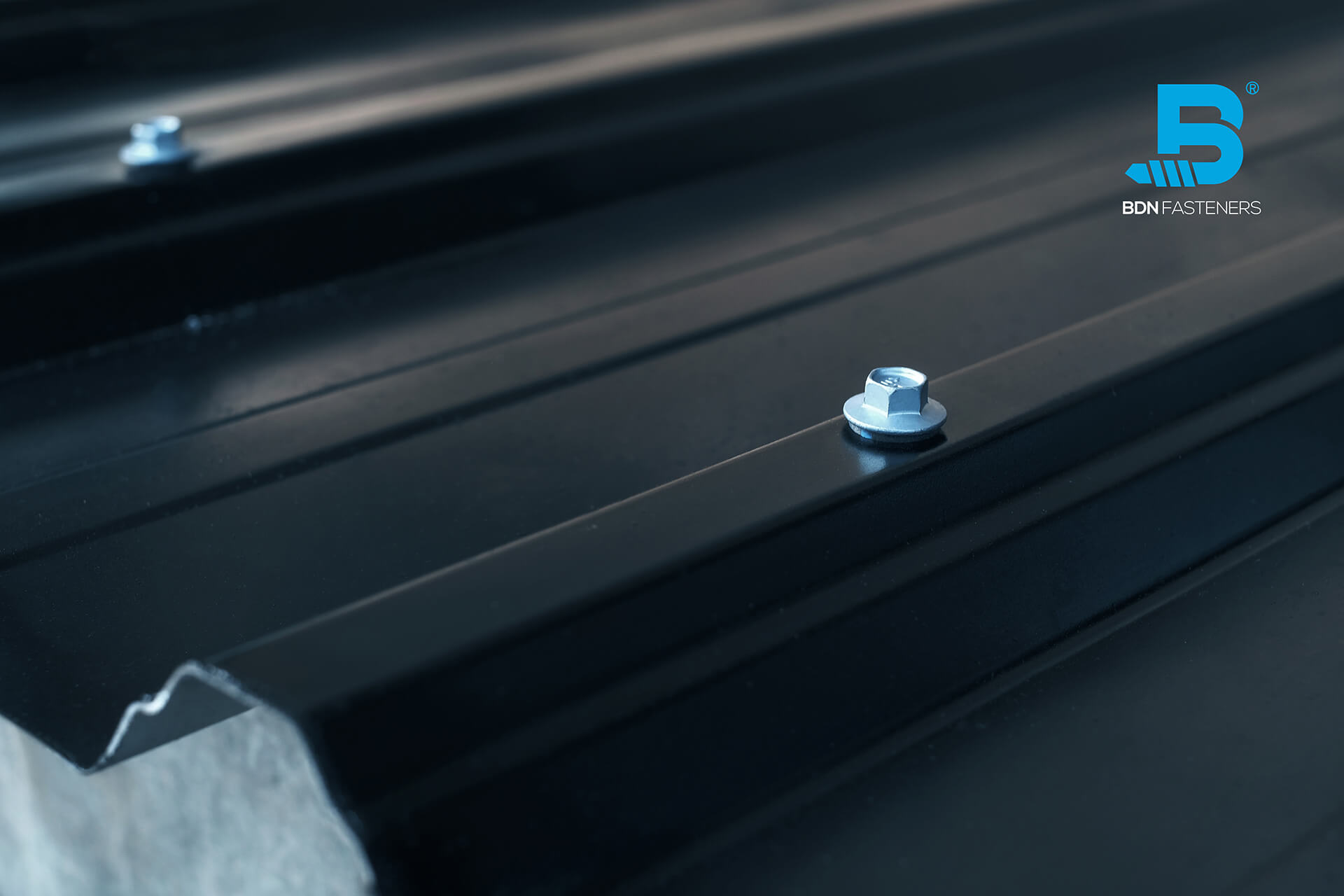

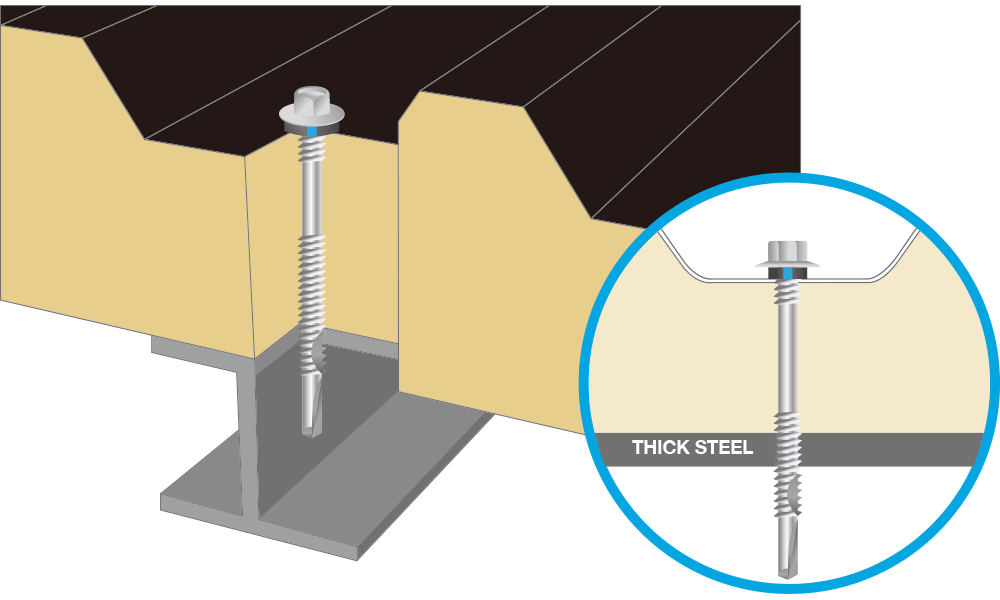

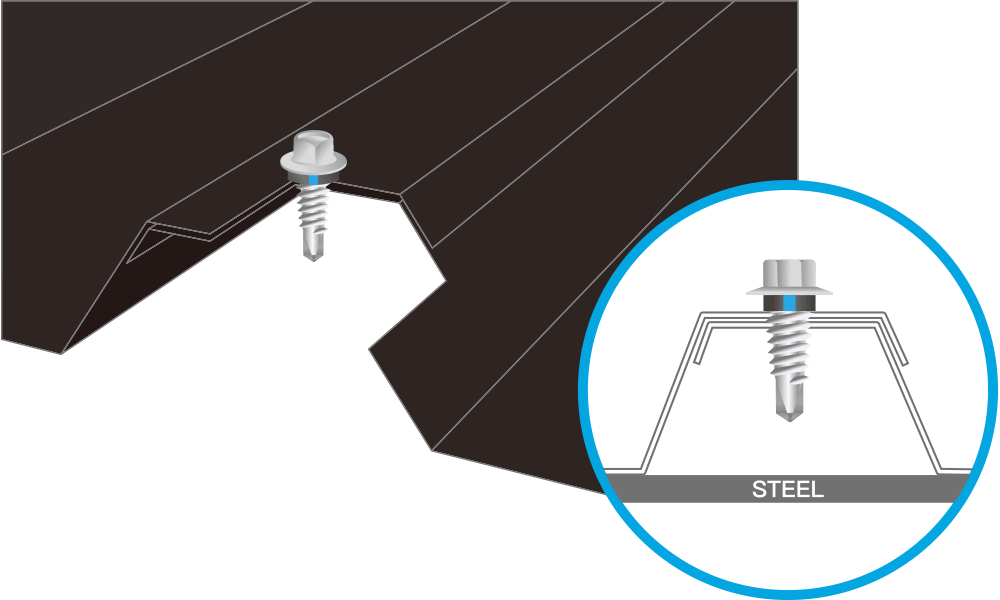

METAL-Tite™ Self-Drilling Screws

BDN Metal-Tite Series sandwich panel screws are made to match various sandwich panel thicknesses; with additional features such as an enlarged hex washer flange to fully cover fully compressed EPDM washers and holes, anti-static EPDM washer to prevent galvanic corrosion, double thread design to increase pullout values, Scratshank to clear excess swarf, and Ruspert anti-corrosive coating for extended lifespan.

BDN Metal-Tite Stitching Fasteners can be used to fix panel to panel side lap, or panel to end lap of light gauge, lightweight steel.

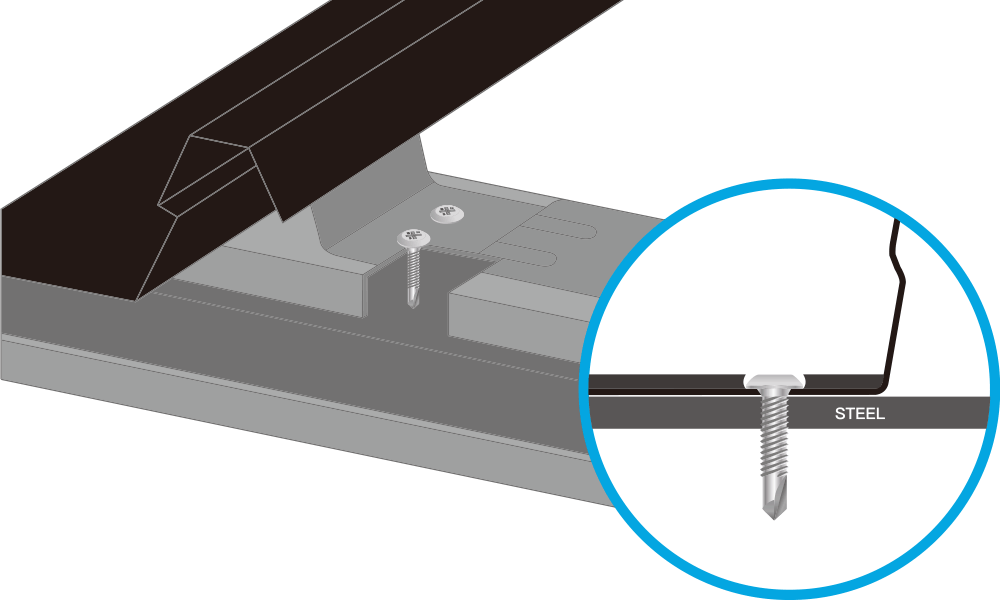

BDN Metal-Tite Wafer Head or Flat Top Concealed Frame Fixing Fasteners for low profile fixing with no visible protrusions which might create interference, creating an aesthetically pleasing flat surface upon installation.

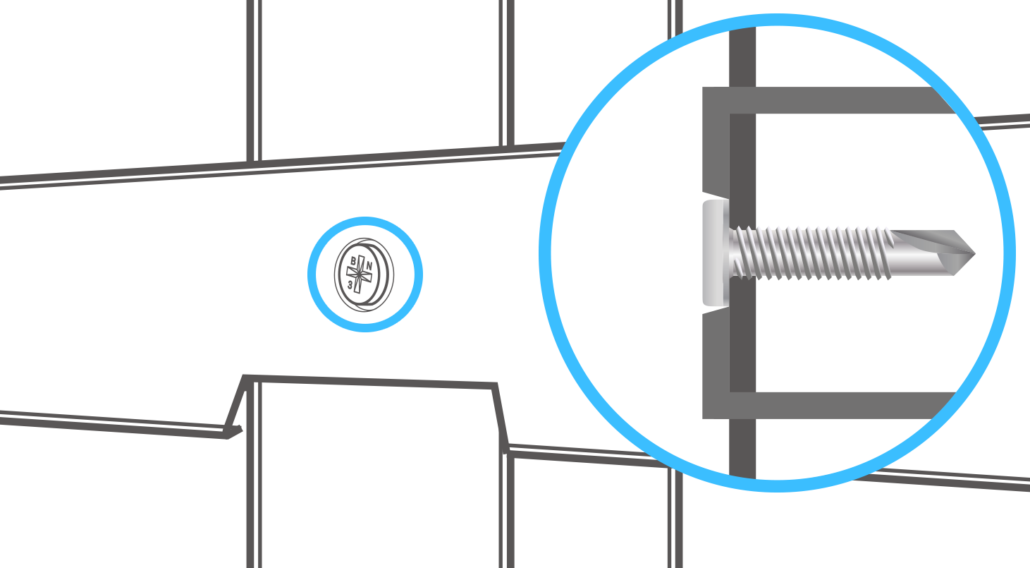

BDN Metal-Tite Truss to Plate connecting fasteners for fixing steel trusses to steel plates or beams which is pretty common on frame and structures for internal roof insulation or wall panels.

Learn more about BDN Fasteners >>

10 Different Self-Tapping screw head types | BDN Fasteners

How to use self tapping screws for metal?

Rust, the most feared phenomenon and common enemy among builders and owners alike of any building structure, especially ones that are exposed to the elements. For coastal areas, salt haze formed by evaporation of sea spray corrodes and weakens the structure and also roofing screws. In other areas, corrosion may result from acids spread from industry, vapors from agricultural fertilizers or pesticides, fumes from petrochemical sites, UV ray exposure, and humidity. Metal roof screws rusting will have negative impact on buildings regardless of its root cause of failure.

The cause and effect of metal roof screws rusting.

When it comes to metal roofing and wall cladding, manufacturers have put in lots of effort in the development of coatings and layering technologies to enhance weathering resistance; some even have up to five layers of coatings, each with its own unique properties to cope with severe environment, and warranted up to 50 years.

A very important aspect that the majority fail to realize is, these roofing sheets will live up to its projected life expectancy only if the screws and accessories used alongside them performs equally well. The overall lifespan of the metal roof covered area depends on whether there are metal roof screws rusting or not. One of the main reasons oftentimes we see really high-tech metal roofing sheets that are fixed with screws that offer little to no weathering resistance at all, which totally negates the purpose of using these high corrosion-resistant sheets in the first place. A responsible roofing sheet salesperson should specify the type of screw with matching weathering resistance when making sales.

The majority of metal roofs are fixed with exposed fasteners, as opposed to concealed fixings roof where the fasteners are covered against the elements; being exposed means that fixings are the first thing that comes into sight when looking over rooftop, and any sign of rust awfully visible, though it is generally overlooked and often not dealt with until it’s too late and damage has spread to the roof sheet or even inside the building.

How to prevent building damage caused by metal roof screws rusting?

We suggest biennial inspections in coastal, high humidity, or highly polluted industrial areas, and quinquennial inspections in rural, less polluted areas. Have an experienced builder or technician examine the site in question alongside you, as they should provide expert opinion on whether the rust is an immediate threat that requires replacement of the fasteners asap, or could be held off until the next season or renovation.

Since having metal roof screws rusting or not is detrimental to the safety and life expectancy of the building, if upon inspection, the roofing screws are really rusty, and the threat of damage imminent requiring immediate action; the following steps will guide you to choosing the correct corrosion resistant screw category for the job.

- Understand your environment. For example, areas close to the coast will be at high risk to corrosion due to high salt content in the atmosphere compared to the inland, and therefore would require high weathering resistant fasteners on structures.

- There are multiple choices on the market when it comes to corrosion resistant coatings, and products are normally priced according its service life and warranty terms and conditions.

- Since it is impossible to tell from the naked eye how effective the coatings really are, a reputable company will provide accredited 3rd party test lab reports as proof of compliance.

For more information on metal roof screws rusting, corrosion resistance and service life in relation to the environment the fasteners are used in, kindly contact your local BDN Fasteners distributor or salesperson, or simply click on Choosing the correct screws for metal roofing sheets installation to understand the scope of warranty for our products and the environment category classification they are base upon. Choose the correct screws to prevent the building impact from metal roof screws rusting.

Learn more about roofing screws >>

Internal Roof Insulation Installation with Self-Drilling Fasteners

How to use self tapping screws for metal?

BDN Fasteners

BDN Fasteners (Broaden Worldwide Co., Ltd) is an ISO-9001 Certified Quality Supplier-Manufacturer of Australian Standard AS3566 self-drilling and self-tapping screws in various coatings for steel to steel and steel to timber applications. Our headquarters are in Taiwan and we operate sales and marketing offices in India and Thailand.

Founded in 2009.